مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

66

56

the question must be asked as to why asphalt mix plants use gasoil instead of the

much cheaper heavier fuel. It must be remembered that cement kilns sometimes

use scrap tyers for fuel and used oil is certainly better environmentally

105

.

Burning used oil in space heaters for small businesses recovers the heat value but

is likely to cause local air pollution

22

and care must be taken here in the equipment

and set up design

23

.

Finally, low temperature burning

of waste oil must be avoided due to the potential

pollutants in gaseous emissions that can be released such as carbon monoxide,

sulphur and nitrogen oxides, particulate matter (PM 10), toxic metals, organic

compounds, hydrogen chloride and dioxins/furans

4

.

Processing Used Oil for Fuels:

1, 107

There are a number of processes that have been applied to condition used oil for

fuel. The treatment is said to be severe processing

22

as compared to the mild

processing needed for direct burning. These processes are in brief as follows

1,

4,107

.

The Propak process:

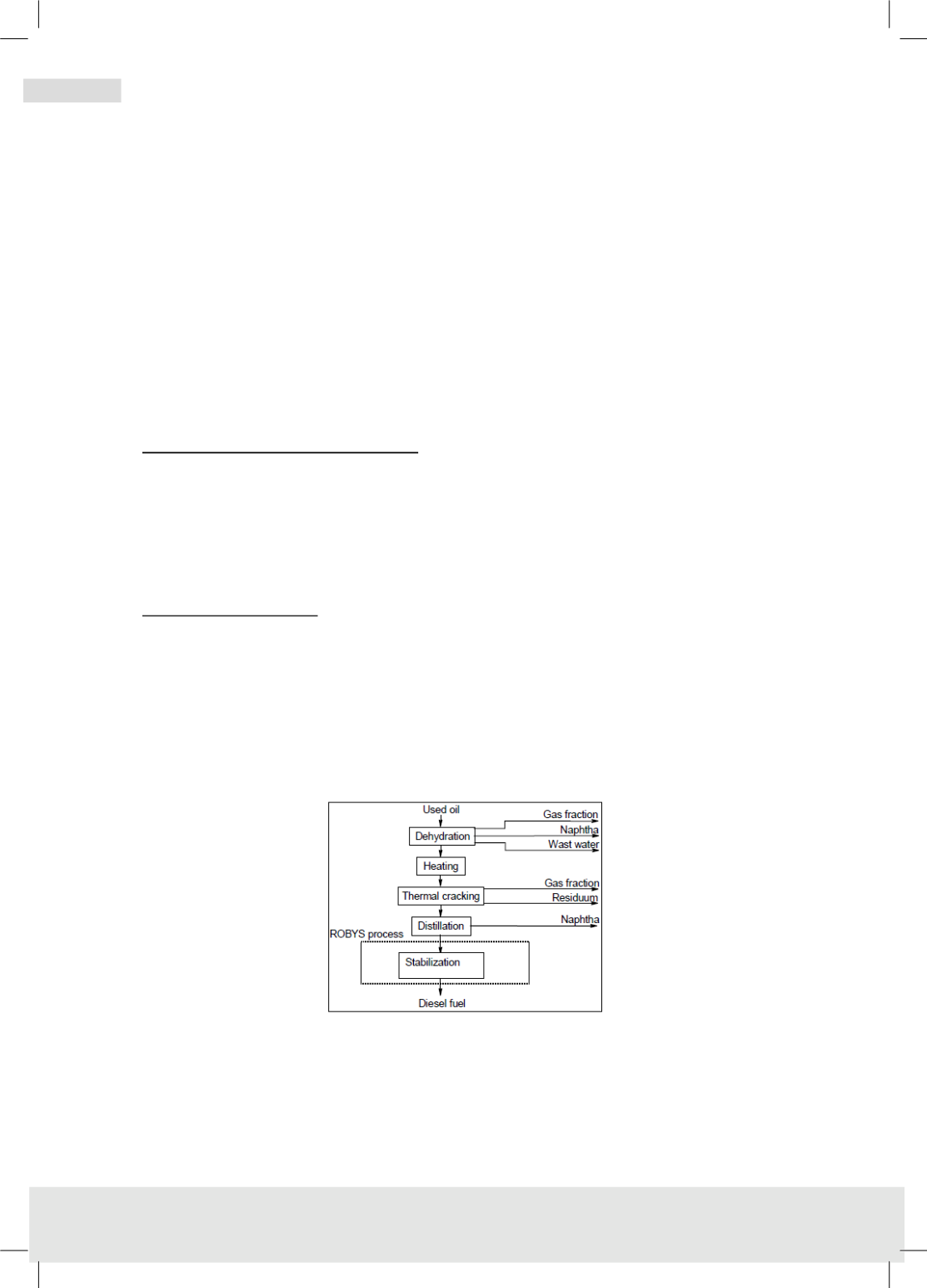

Fig (15). This process involves thermal cracking of the used oil followed by

distillation and stabilization to produce gasoil (diesel) and fuel oil. Used in

Canada and Belgium but the product quality is poor with respect to sulpher. Gas

fraction and naphtha may be used as process fuel.

Fig (15) - Propak process

–

source 107