184

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

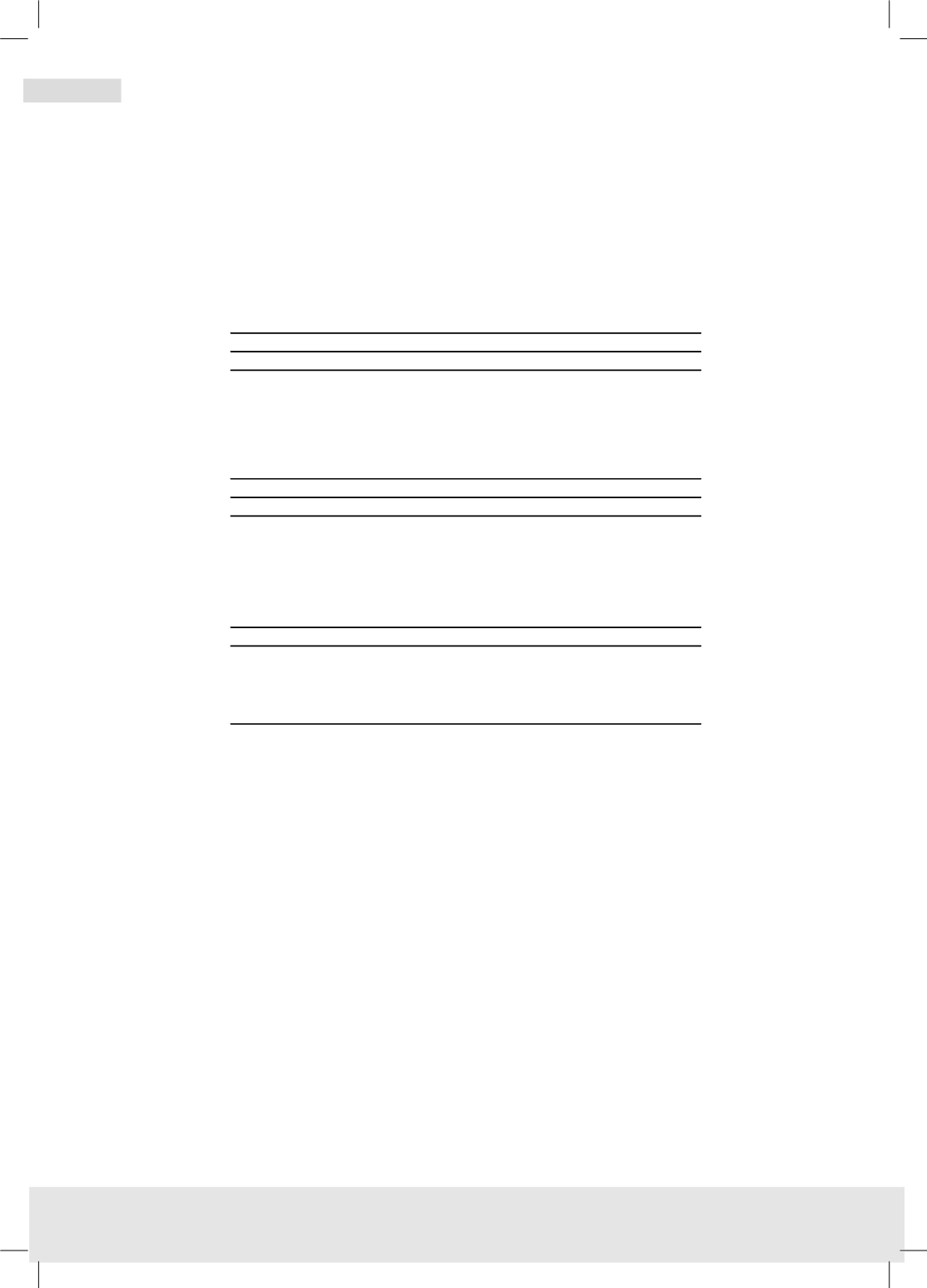

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

61

8.2

Feedstock and product analyses

.

Table 5 shows process figures, including used oil composition, product´s characteristics

and utilities consumption. It is claimed that 95% of the oil fraction present in the used

lube oil feedstock is recovered. These data have obtained from CEP website.

Table 5 Process figures of the STP project

Source: STP

8.3

Process economics

For the purpose of the economic evaluation, the following assumptions have been

made:

Plant capacity: 120000 metric tons per year

Plant location: Gonfreville, France

Cost basis: 2012/2013

Stream factor: 8000 hours

Depreciation: 10 years

Process figures

Composition, wt% Normal Min-Max

Water

5.0

2.0-10.0

Light ends

2.0

1.0-4.0

Gas oil

3.0

1.0-4.0

Oil fraction

78.0

65.0-18.0

Asphaltic Residue

12.0

10.0-18.0

Characteristic

ASTM Light fraction Heavy fraction

Color

D1500

2.0

2.3

Density

D1298

860

868

Viscosity, cst @40ºC

D445

15-20

30-50

Flash point, ºC

D 92

205

220

Sulfur content

D4294

0.30

0.35

Metal content, ppm D6595

<10

<10

MP Steam, Kg/h

3400

Thermal oil, Kcal/h x 10

6

3.60

Cooling Water, m

3

/h

490

Electric power, Kwh/h

320

Used lube oil composition

Product characteristics

Utilities Consumption