البحـث الثاني

179

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

56

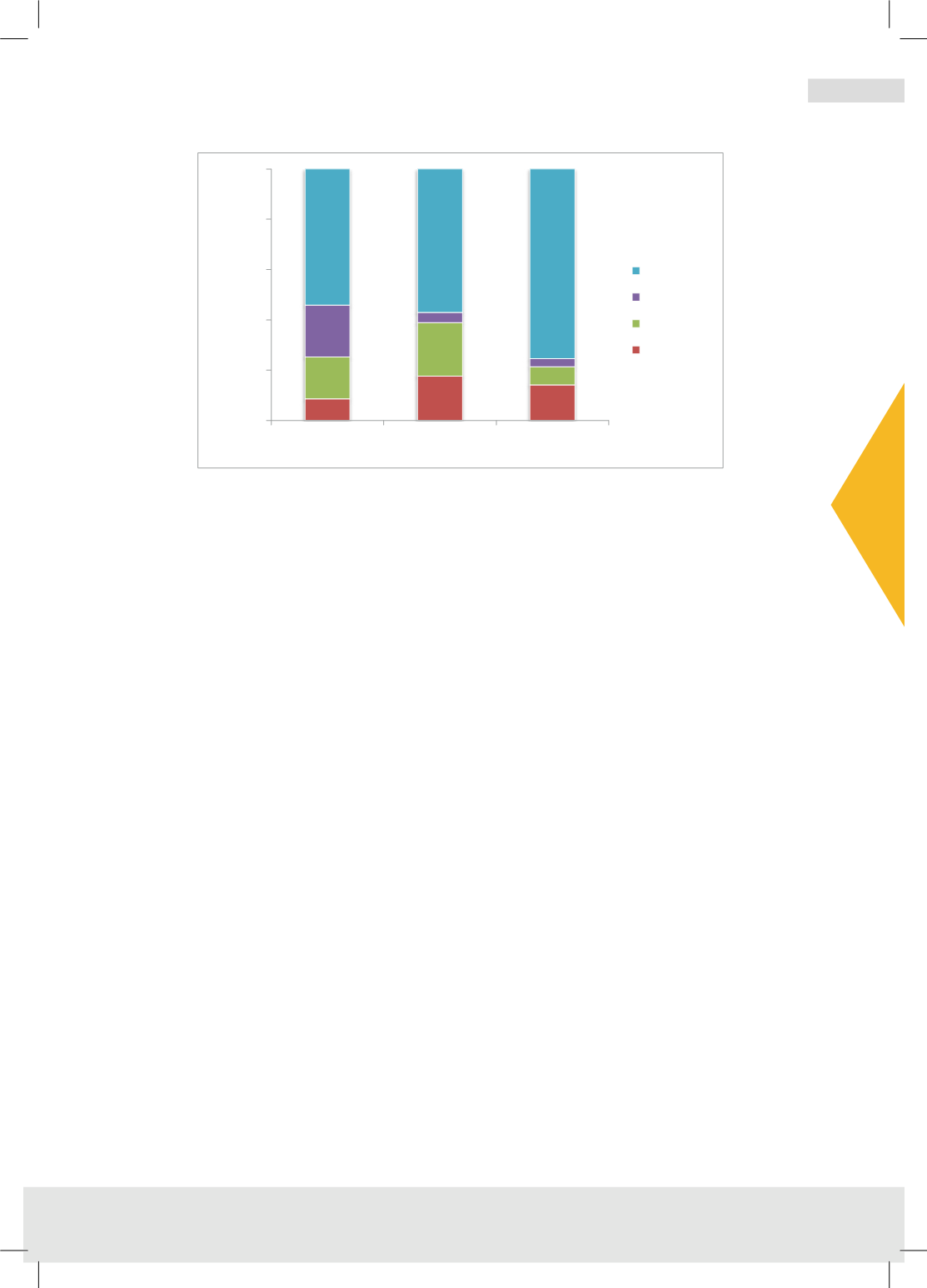

Figure 30 Operating costs for different re-refining technologies

Source: Own elaboration with data from (Audibert, 2006)

7.1.3 Capital costs

Graziano and Daniels (1995) have concluded in their study that the capital costs

associated with re-refining have long been identified as an obstacle to the expansion of

the re-refining industry. For the specific case of Middle East/North Africa region, the

capital costs structure is a mixture of the costs of imported equipment and material

together with local costs such as feedstock, utility and labor. These costs are in general

site specific and usually location factors are used to convert them to local conditions.

The fact that the most important cost factors such as engineering, equipment, skilled

labor, erection, etc., have to be outsourced aggravate the investment cost which is a

strong function of the technology employed. Contrary to what one might think, the

relation between the investment costs and the production capacity is not linear.

Increasing the capacity ensures the economies of scale and costs savings. Figure 31

shows the variation of capital costs versus capacity for a grassroots re-refinery based on

CEP/Mohawk technology described earlier. It also highlights the fact that the relation

between the investment costs and the production capacity is not linear. The higher the

capacity of the plant, the less the capital cost is required per metric ton of used oil

processed. For a 50000 MTPY capacity, the capital costs amount to US$ 40 million.

Doubling the capacity to 100000 MTPY increases the capital costs by only 55%. Just like

in crude oil refining, the economies of scale are an important factor to consider in re-

refining profitability.

54,2%

57,0%

75,5%

0,0%

20,0%

40,0%

60,0%

80,0%

100,0%

Safety Kleen

Sotulub

Revivoil

Fixed costs

Chemicals

Labor

Utilities