مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

78

68

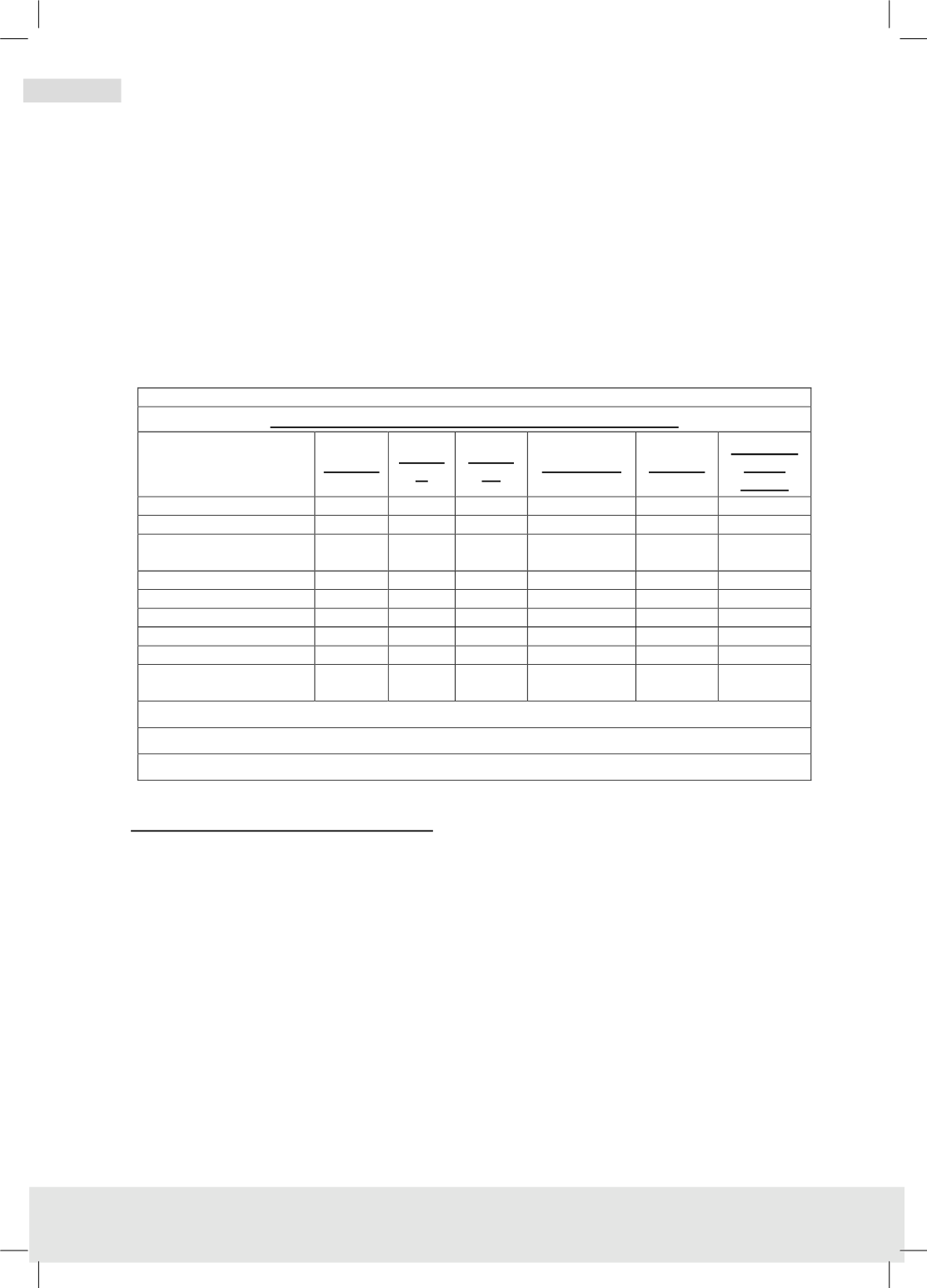

Table (13) shows global base oil refining capacity

103

in various regions of the

world, which is much higher than the demand projections provided above. In a

January 2016 article about ICIS lube conference in Dubai

42

, it was suggested that

base oil facilities were operating at 65% of capacity in 2015 and that the surplus

capacity stood at 19 million tons a year. The surplus is forecast to grow to about

22 million tons a year by 2020. The new capacity additions in groups II and III

are about 7.5 million tons a year by adding up the new capacities between 2013

and 2016 only

37

. Some rationalization is expected especially in phasing out group

I capacities but the fact remains that surplus capacity is going to weigh on the

market and this does not bode well for the re-refining industry.

Table (13)

Global Base Oil Refining Capacity 2014 - 1000 barrels/day*

Group I Group

II

Group

III

Naphthenic

TOTAL

Additions

2014 -

2015**

North America

75.0

157.8

2.0

48.1

282.9

2.4

Western Europe

113.6

5.5

8.6

10.4

138.1

14.0

Central & Eastern

Europe

86.0

1.4

2.6

0.0

90.0

7.0

S.Asia/Pacific/Australia

63.7

46.8

16.0

0.0

126.5

5.2

Middle East & Africa

68.9

6.0

30.2

0.0

97.1

11.0

China

39.5

68.6

7.0

23.7

138.8

34.3

Japan & Korea

32.5

60.3

50.9

3.6

147.3

13.0

TOTAL

479.1

346.3

117.3

85.8

1020.6

86.9

TOTAL Million tons a

year

24.4

17.7

6.0

4.4

52.1

4.4

* Includes only solvent extraction and hydro-finished re-refining capacity

** This list is not exhaustive and there could be more

Source: (103) Lubes'N'Greases 2014 Guide to Global Base Oil Refineries

The Impact of Process Selection:

Process selection by itself depends on many factors and not just economic. Is the

project in a country with a good and well controlled collection system? Are the

laws and regulations supportive of a re-refining project? Apart from the used oil

feed, are other raw materials available or not? Is the project inside or close to a

petroleum refinery where exchange of materials, reduction of safety and security

cost is possible? This is particularly important with respect to hydrogen supply if

the selected process is of the hydro-treating type. How big is the re-refining

project under consideration? To start with it should be as big as the collection

system can support in a sustainable manner. At the same time some processes are

suitable for large plants and others for small plants. The modern plants which

produce good quality hydro-finished oils are much more economical than small

plants of the same technology.