مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

80

70

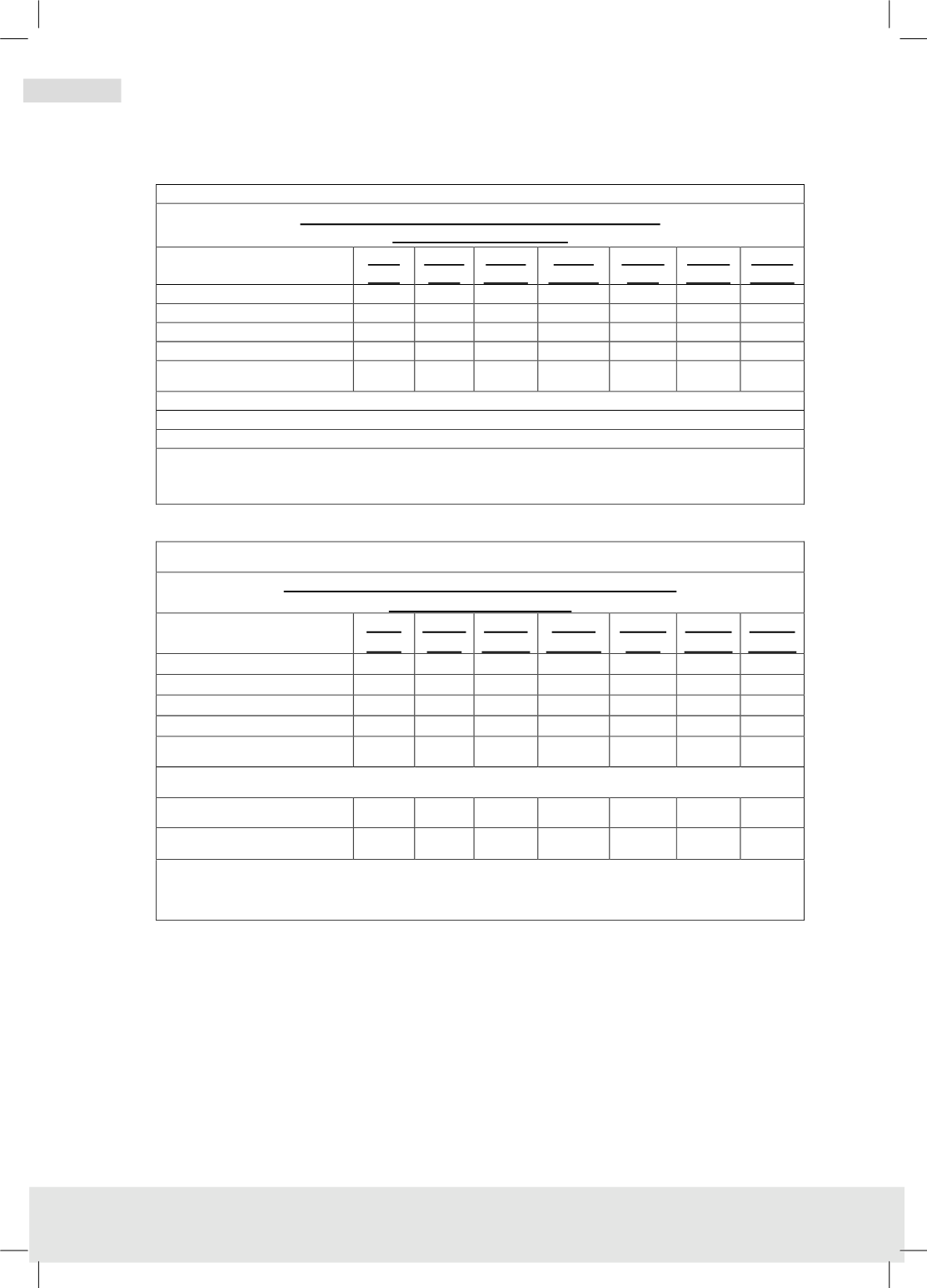

Table (14)

Derived Used Oil Fee Euro/ton for Various Processes

100 thousand tons/y Plant

Acid

Clay

TFE+

Clay

TFE+

Hydro

TFE+

Solvent

TDA+

Clay

TDA+

Hydro

PDA+

Hydro

Capacity 1000 ton/year

100

100

100

100

100

100

100

Capital cost million Euro

34

37

57

49

45

69

61

Operating Cost Euro/ton

152

165

214

202

280

304

248

Revenue Euro/ton

177

203

251

226

211

252

224

Used Oil Fee Euro/ton

-25

-37

-37

-24

69

52

24

TFE = Thin Film Evaporator

TDA = Thermal Deasphalting

PDA = propane Deaspahlting

Source: Adaptation from (1). Simple averages of cited plants in Europe. Based on GEIR,

CONCAWE & TN Sofres. Plants capacity has been normalized to 100 to make the comparison more

representative.

Table (15)

Derived Used Oil Fee Euro/ton for Various Processes

35 thousand tons/y Plant

Acid

Clay

TFE+

Clay

TFE+

Hydro

TFE+

Solvent

TDA+

Clay

TDA+

Hydro

PDA+

Hydro

Capacity 1000 ton/year

35

35

35

35

35

35

35

Capital cost million Euro

17

19

29

25

23

35

31

Operating Cost Euro/ton

244

265

343

323

449

399

399

Revenue Euro/ton

177

203

251

226

211

252

224

Used Oil Fee Euro/ton

67

63

92

98

238

52

175

Used Oil Fee Comparison of Two Capacities

Capacity 100

-25

-37

-37

-24

69

52

24

Capacity 35

67

63

92

98

238

147

175

Source: Adaptation from (1). Simple averages of cited plants in Europe. Based on GEIR,

CONCAWE & TN Sofres. Plants capacity has been normalized to 35 to make the

comparison more representative. The used oil fee is compared for two cases.

Comparison of the two cases reveals that all processes need subsidy when the

plant is of small capacity and that subsidies per ton of used oil feed increase when

the plant is smaller as displayed in Fig (22).