164

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

41

.

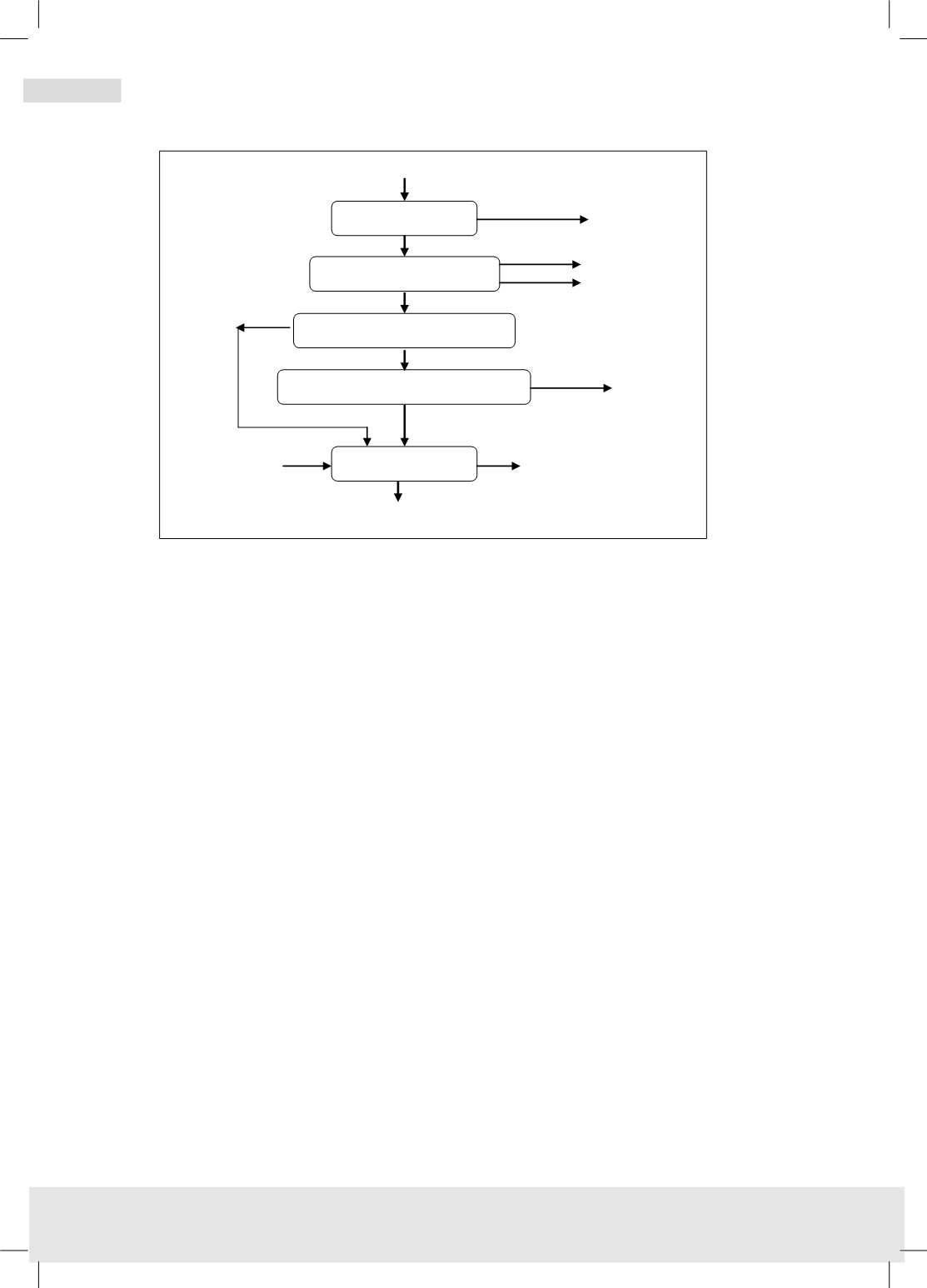

Figure 23 RTI simplified block flow diagram

Source Giovana et al (2003)

4.17 SOTULUB technology

This technology was developed by Societe Tunisienne des Lubrifiants (SOTULUB). It is

based on the injection of a strong base at various stage of the process.

4.17.1 Process description

The SOTULUB process consists of the following steps:

Dewatering:

In this section, water and light hydrocarbons present in the used oil are separated by

flashing: Used oil entering the process unit is preheated in heat exchangers at about

160°C by recovering the heat of the distillates from the distillation and fractionation

columns then mixed with a small ratio of ANTIPOLL. Antipoll, an alkaline product, is

injected to the used oil under dosing rate control. The mixture is drawn into a flash

drum were water and light hydrocarbons are separated under atmospheric pressure

and then treated separately.

Gas oil stripping:

In this section, gas oil present in the dehydrated used oil is separated under vacuum.

The dehydrated oil is heated again to approximately 280°C and drawn to a stripper

Base Oil

Light

Hydrocarbons

Water

Residue

Light Base

Clay

Used Clay

Used Oil

Cyclonic Vacuum distillation

Dewatering

Flash Distillation

Vacuum Distillation

Adsorption

Water