البحـث الثاني

161

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

38

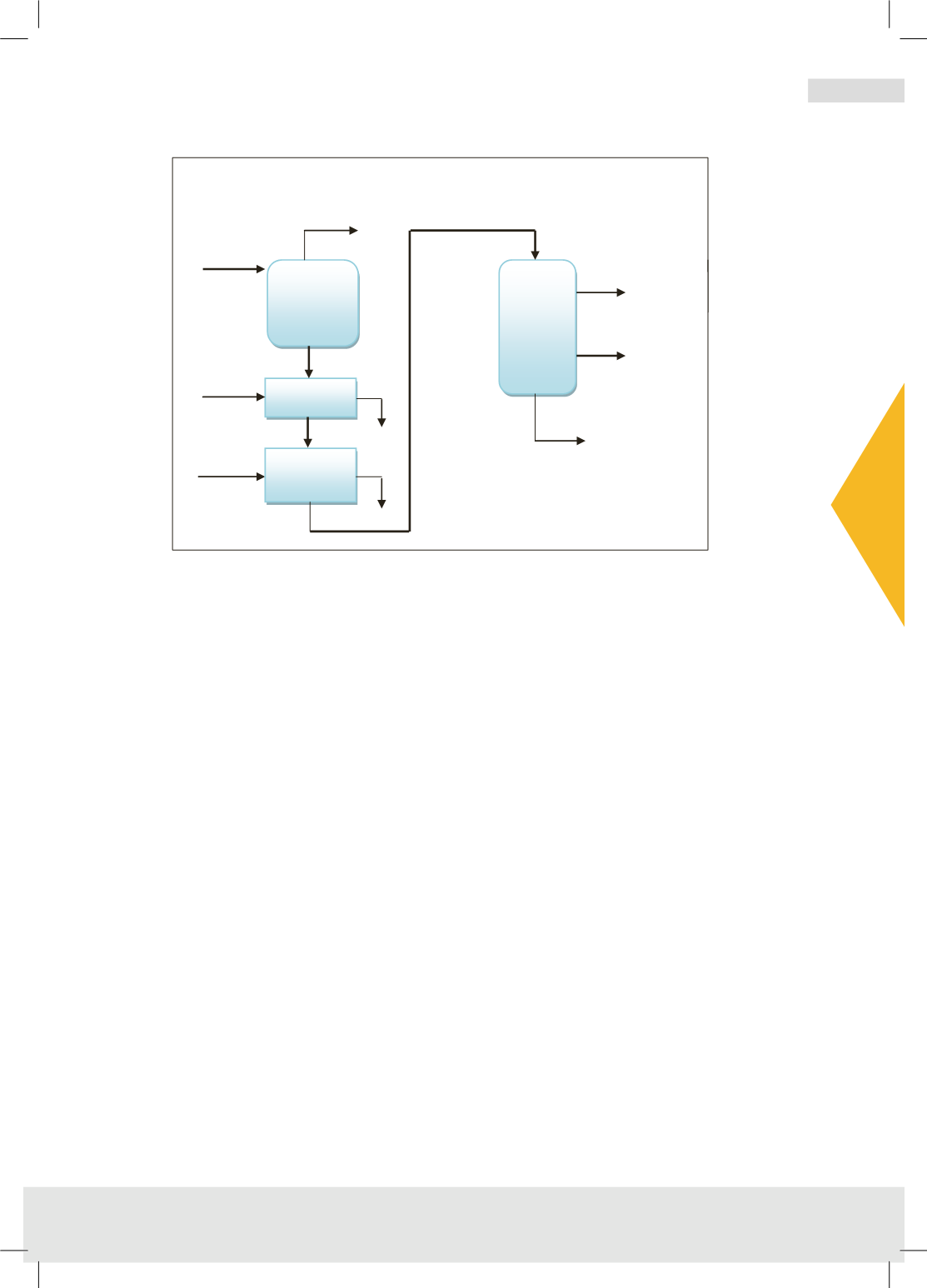

Figure 21 Acid/Clay re-refining process

Source: Giovanna et al ( 2003)

4.15 ENTRA technology

This technology developed by the ENTRA Company is similar to the distillation/clay

treatment approach, being also based on distillation and clay polishing. The difference

lies in the fact that the vacuum distillation is carried out in tubular reactors.

4.15.1

Process description

The basic steps of this process are as follows:

Preliminary stage:

A vacuum distillation stage at 130ºC and 100 mm Hg. pressure. The stage involves the

separating out of water and light elements.

Cleaning stage:

In the tubular reactor, the used oil gets converted into a vapor due to the rapid increase

in temperature. The vapor is then subjected to fractionated condensation. The

evaporation process is produced by injection of the oil at a constant speed and at a

Gas Oil

Derivative

Base Oil

Acidic

Sludge

Clay and

Filter Waste

Water and

Light

Products

Waste Oil

Acid

Clay

Asphalt

Distillation

Clay

Treatment

and

Filtration

Acidification

Clay

Treatment and

Filtration