162

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

39

temperature of 400ºC. The oil obtained in this stage is free of solid impurities, and metal

and other elements.

Discoloration and purification stage:

At this stage, the visual appearance of the base oils is improved. The chlorinated

compounds are removed through the addition of Sodium.

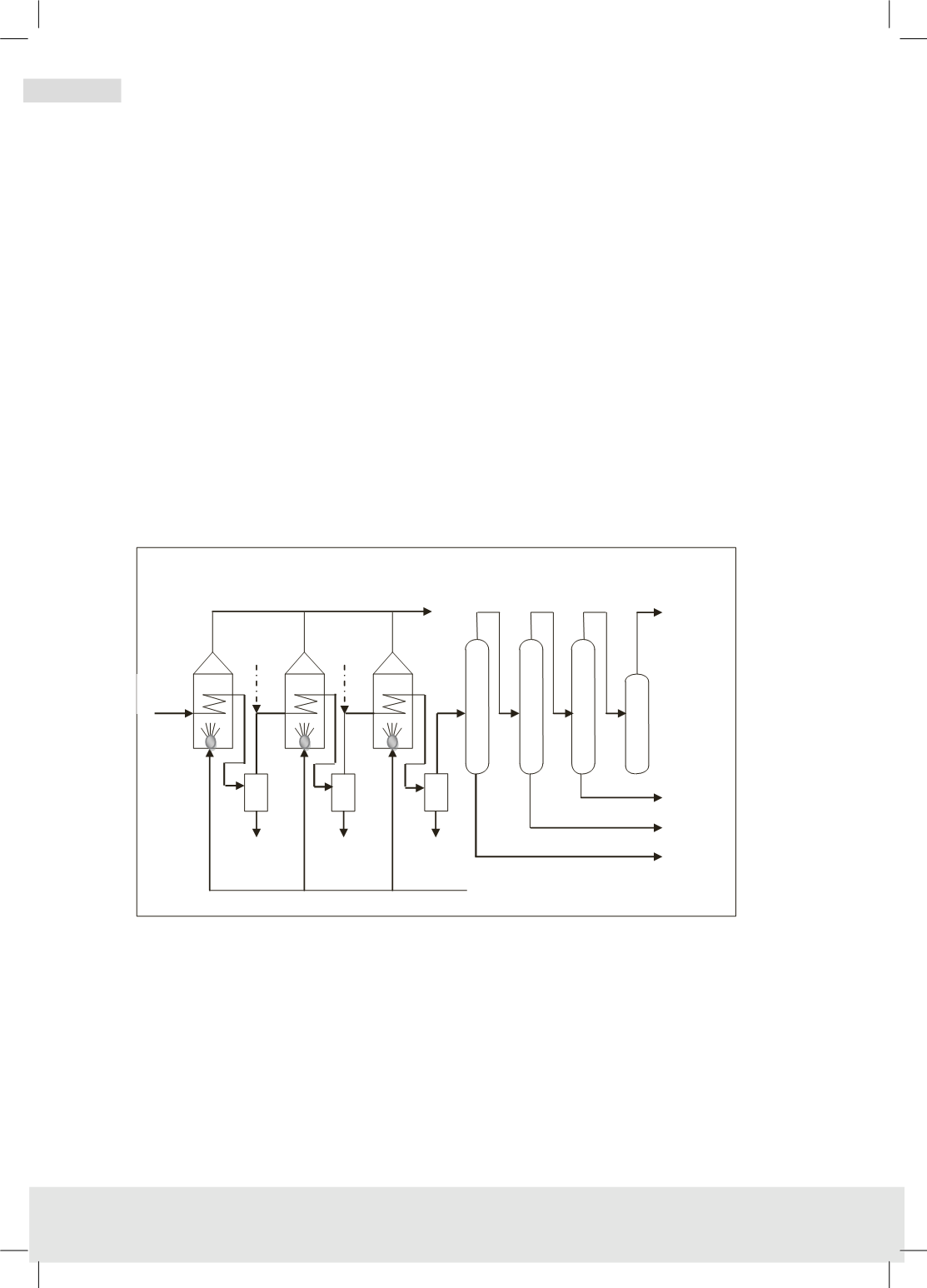

The simplified process flow diagram is illustrated in Figure 22

4.15.2

Process features and drawbacks

It is claimed that it is a high performance process in which control of the temperature is

highly important for obtaining the required results. The process is considered to be

clean technology according to the IACT (International Association for Clean

Technology). The TÜV analysis (Technische Überwachungsverein) shows the total

elimination of PCBs. The main drawback is the handling of sodium, which is complex

and hazardous.

Figure 22 ENTRA simplified process flow diagram

Source

: Audibert (2006)

Waste

oil

Fuel

gas

Diesel oil

Base oil

Spindle

Fuel

Vacuum

towers

Fuel

Tubular

reactors

Clay

Sodium