البحـث الثاني

165

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

42

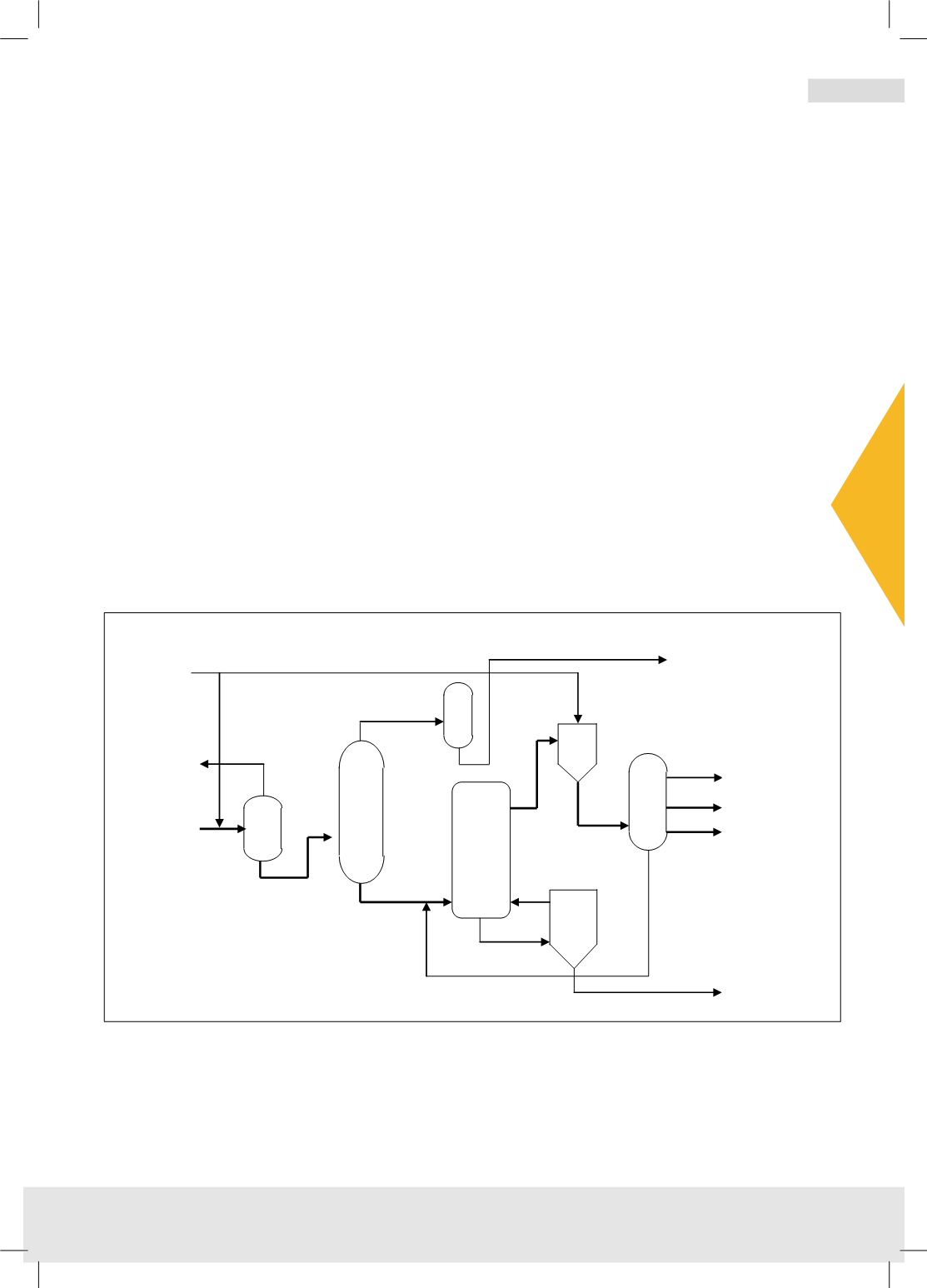

where gas oil is removed from the oil under vacuum, then condensed and stored for

eventual reuse.

Vacuum distillation:

In this section the lubricating fractions contained in the used oil are distilled out under

high vacuum conditions: The stripped oil is delivered to a distillation column coupled

with a thin film evaporator where it is distilled under high vacuum. This operation

results in a distillate and a bottom asphaltic residue where heavy metals, chemical

additives, polymers and degraded products are concentrated. The residue is stored then

reused for other ends. The unflashed oil flows under gravity to the thin film evaporator.

The flash vapours generated in the evaporator flow to the distillation column where

they are fractionated into light and heavy distillates.

The simplified process flow diagram is shown in figure 24.

4.17.2

Process features and drawbacks

In this process no finishing step is required hence a decrease in the investment cost but

a low quality product. The process is based on KTI technology which was modified by

Sotulub which operates a 16000 tons/y plant in Tunisia.

Figure 24 SOTULUB simplified process flow diagram

Source: Sotulub

Heavy Base Oil

Gas Oil Drum

Thin Film

Evaporator

Fractionation

Column

Water + Light

Hydrocarbons

Flash drum

Vacuum Distillation

Used oil

Antipoll

Gas Oil

Gas Oil

Light Base Oil

Residue

Gas Oil Stripper