مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

46

36

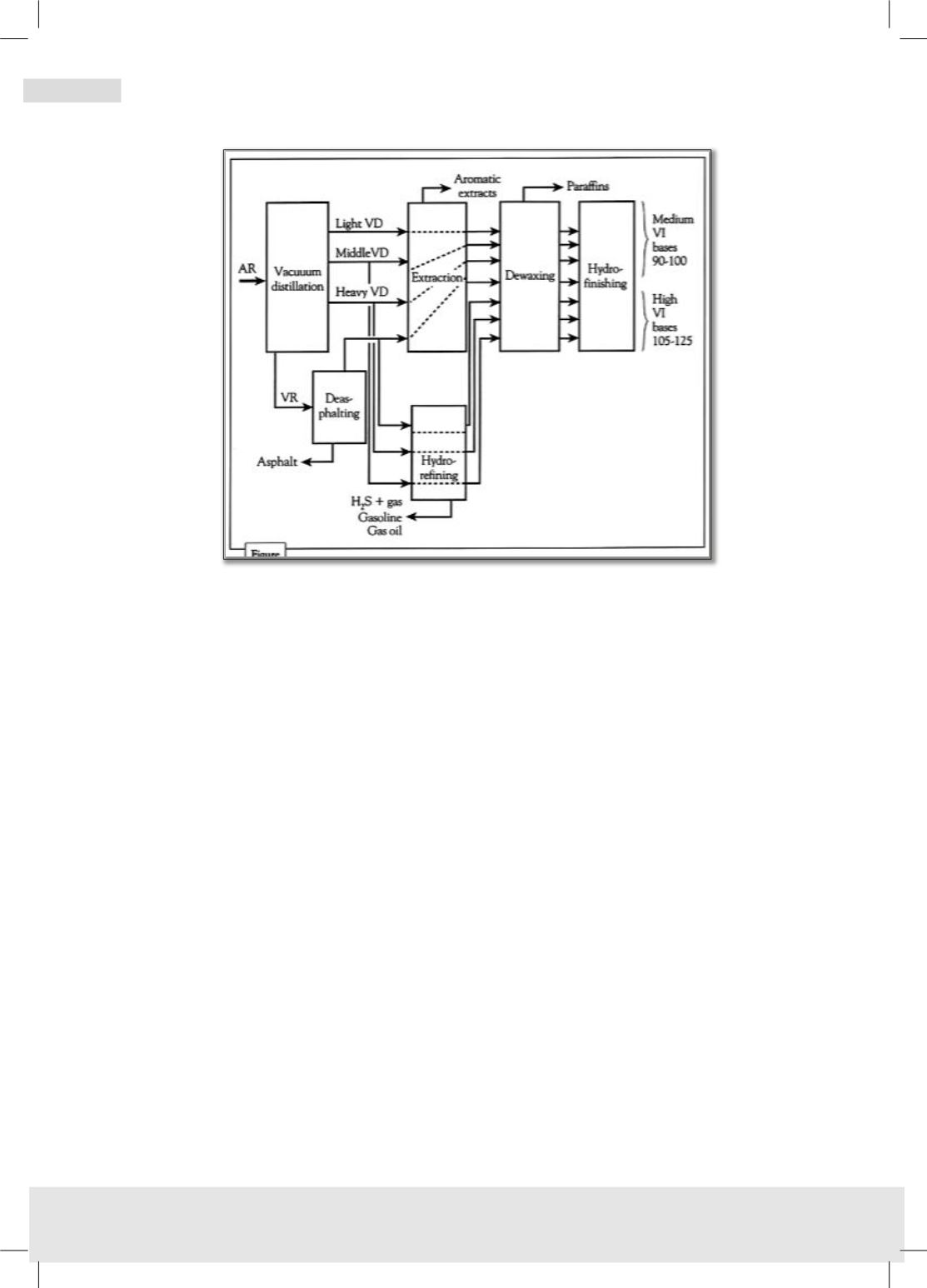

Fig (1) Virgin Lube Processing - Source: 2

Finally the lube cuts are sent in turn to a hydrofinishing unit to improve colour

and remove sulphur and nitrogen compounds making the cuts ready for

blending with additives according to the desired grades.

There are variations to the above steps where, for instance, the vacuum cuts

and DAO can be hydrotreated to saturate aromatics and remove contaminants

before the dewaxing stage and final distillation for the respective base oil cuts

as shown in Fig (2).

Similarly catalytic dewaxing sometimes replaces solvent dewaxing and thus

saving a lot in solvent cost. “Catalytic dewaxing was a desirable alternative to

solvent dewaxing especially for conventional neutral oils because it removed

n-paraffins and waxy side chains from other molecules by catalytically

cracking them into smaller molecules.”

1