مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

48

38

1-

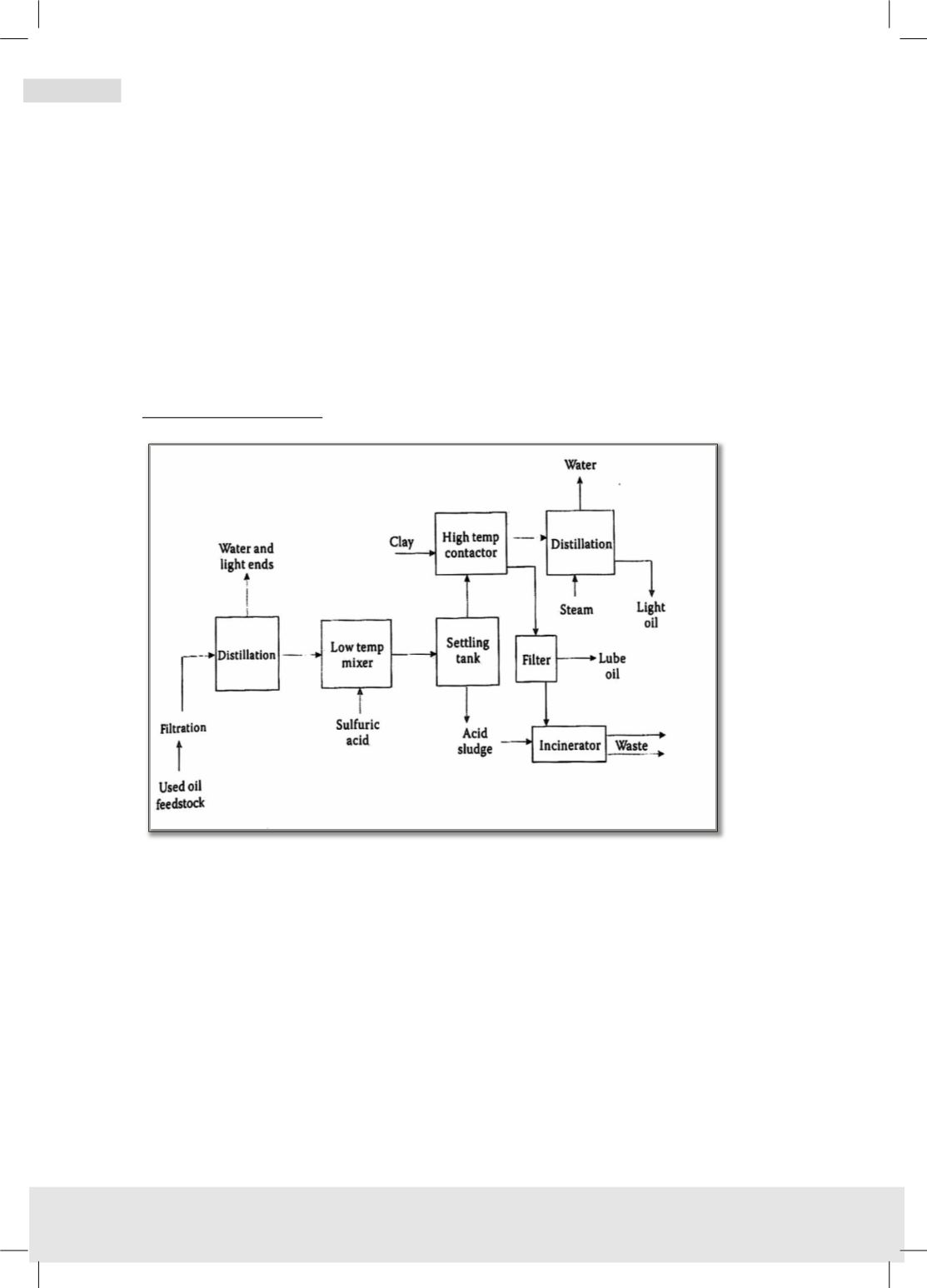

Treatment with sulphuric acid and clay.

2-

Using a distillation process followed by activated clay treatment.

3-

Treatment by solvent extraction to reject heavy residue, metals and

other contaminants.

4-

Using either 2 or 3 followed by hydro-treatment of the product to

improve the quality further.

There are many processes for the treatment of used lubricating oils but here the

most famous are discussed.

The acid/clay process:

1, 3, 107

Fig (3) - Acid/Clay Process - Source: 1

Fig (3). After settling and filtering, the used oil is heated to 120

o

C and distilled in

a pre-flash tower to remove entrained water and light hydrocarbons. Contact with

sulphuric acid follows to remove contaminants such as oxygen, nitrogen and

sulpher compounds in addition to resins, asphalt and metals. The stream then

passes through active clay at 270

o

C to remove odour and improve colour.

This process, while simple, inexpensive, proven and easy to operate is mired with

environmental problems due to acid emission and sludge. The sludge disposal is

neither easy nor inexpensive. The spent clay goes to ceramic and cements

industries or incinerated. The base oil quality is very low

1

and the yield is close