مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

50

40

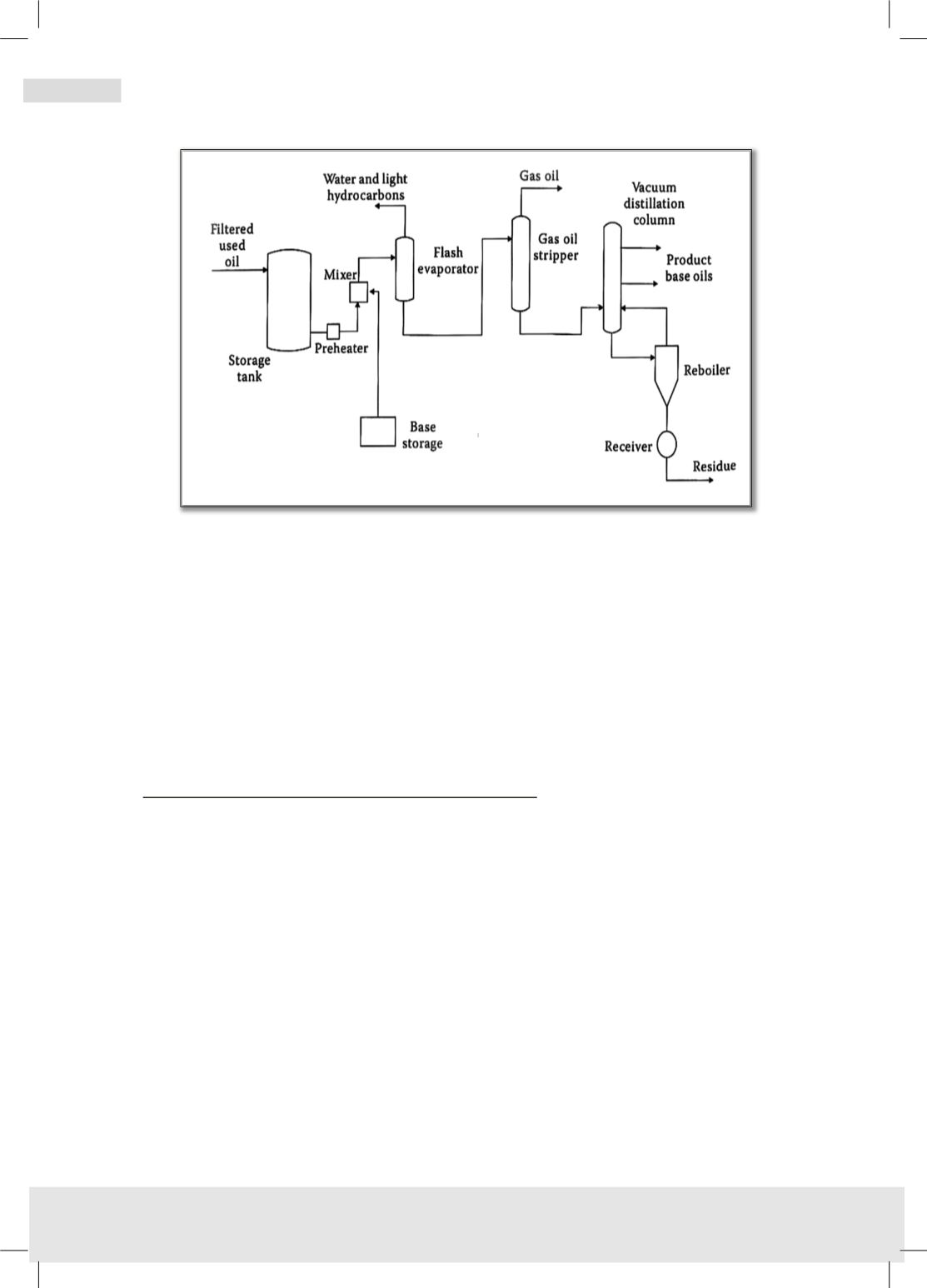

Fig (4)

–

Sotulub Process

–

Source 1

the reboiler can be replaced by a centrifuge to separate the asphalt and heavies

3.

The base oil yield

is 62.76%

1

.

Two units are reported, one in Tunisia at 16 thousand tons a year and in Kuwait

at 20 thousands. But Tunisia is said to have added another stage later to hydro-

treat the products and improve the quality.

The Mohawk and CEP Mohawk Process:

1, 3, 107

In the early 1980s, a plant was constructed in Vancouver, Canada at 600 barrels

a day to treat used oil by subjecting it to a chemical treatment by a hydroxide or

a combination of this and a weak acid. Water and gasoline are then removed by

flash distillation and then gasoil is removed by vacuum distillation. The final step

uses another vacuum step and a thin film evaporator to get the base oil cuts and

bottom’s asphalt combined with the unwanted contaminants. The yield of base

oil is 65%. A hydro-treating step can be added for the full base oils cut before

final distillation breaks them into the desired cuts of Group I base oils as shown

in Fig (5).