البحـث الأول

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

51

41

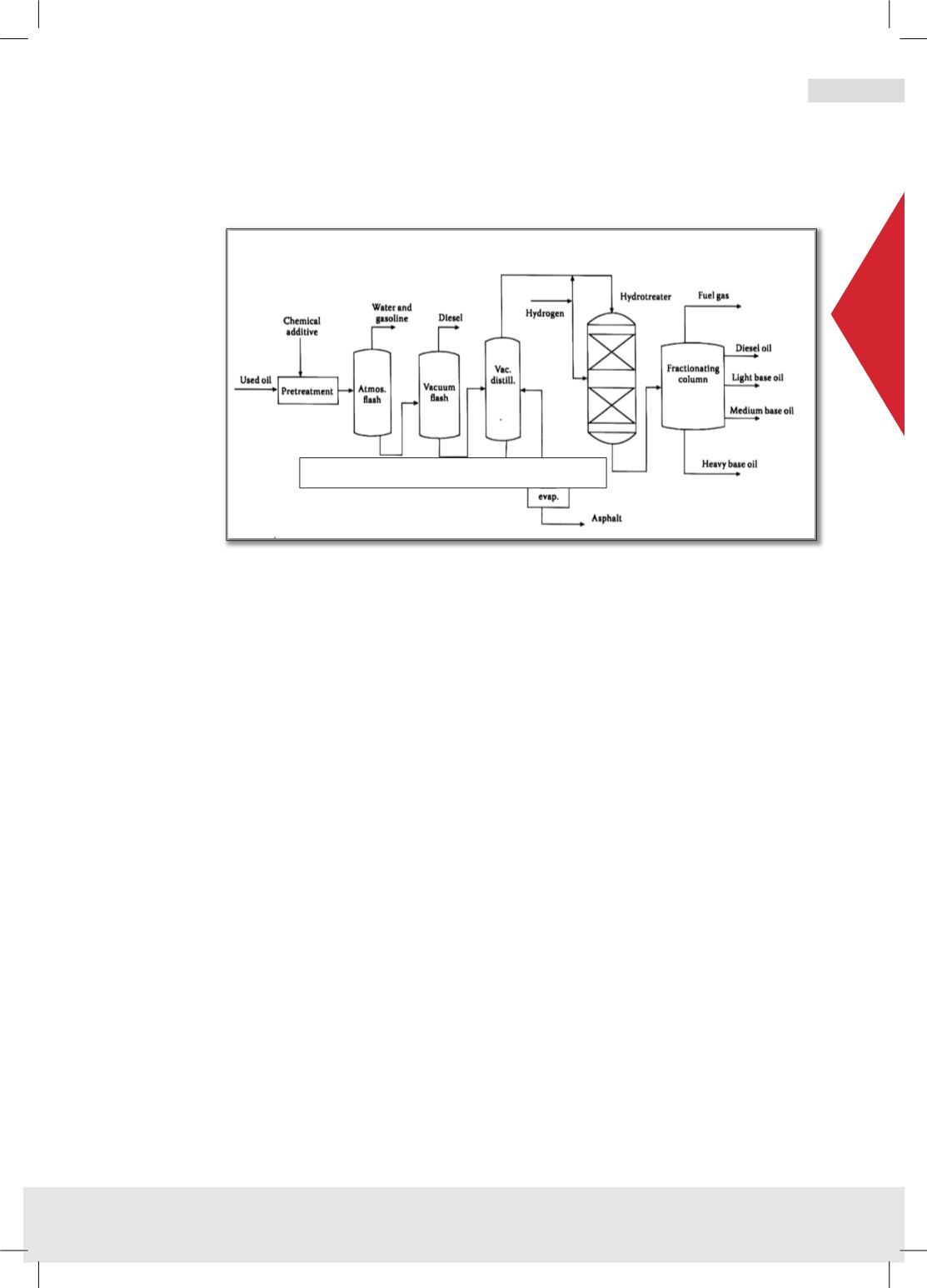

Fig (5) - Mohawk Process with Hydro-treater - Source 1

However, Mohawk and Chemical Engineering Partners (CEP) later combined to

use the initial stages of the Mohawk process and adding a hydro-treating stage of

three reactors in series operating at a pressure of 1300 psig and 315

o

C to reduce

sulpher and other contaminants and to improve base oil yield to the level of group

II base stocks as shown in Fig (6).

CEP's leading technology since 1988 is said to produce API Group II quality base

oil with recoveries in excess of 70%

93

. CEP licenses a number of re-refining

plants where ten are operational globally and two more in design, approaching

nearly a total of billion litres of re-refining capacity

93

which can produce Group

II base oils.

The minimum economic size, according to CEP

1

, is 15 thousand tons a year and

the yield of base oil is 74%, 4% light oil, 4% gasoil and 13% asphalt, a great

improvement over the original Mohawk. The process is used in Canada, USA and

Finland, Australia (20 thousand tons a year) and Indonesia (50 thousand tons a

year Mohawk).

Fig (4) Sotulub Process. Source: 1