البحـث الأول

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

59

49

bottom stream is fractionated in a vacuum tower for naphtha, diesel and base oil

cuts.

The process produces Group II+ quality base stocks. In the Puralube plant in

Germany 45 thousand tons a year of high quality base stocks are produced in

addition to 25 thousand tons of other products. The plant was completed in 2004

and duplicated in 2008.

Puralube

86

is planning with UOP to upgrade one of its re-refineries to produce 50

thousand tons of Group III base oils in the first quarter of 2017. But the fall in oil

prices may put this plan on hold

86

.

STP Process:

94, 107

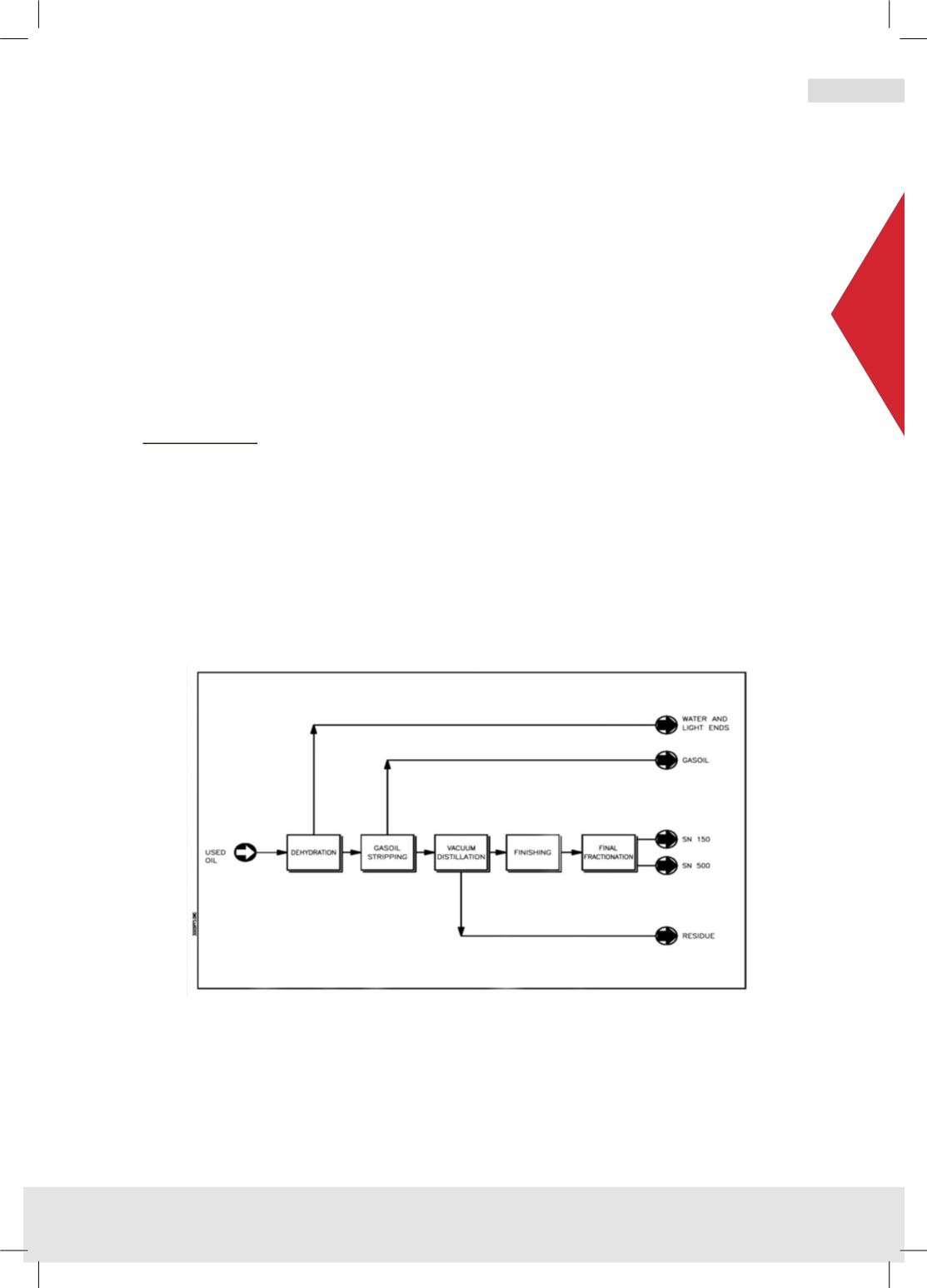

Fig (13). After settling and filtration, dehydration and removal of light ends is

done in an atmospheric tower at 160

o

C. The light ends may include gasoline,

solvents and glycol.

The second step is a vacuum tower to recover gasoil before the third step of

vacuum distillation accompanied by a thin film evaporator to recover vacuum gas

oil (VGO) leaving the asphaltic residue with most of the contaminants (metals,

polymers, carbon and dust) drawn from the bottom.

Fig (13) - The STP Process - Source 94

The VGO is then either treated chemically if the process is to produce API Group

I base stocks or hydrotreated if API Group II are to be produced. The hydro-

treatment process as usual removes further contaminants such metals, sulpher,

chlorine, oxygen, PCBs and PNAs.