مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

56

46

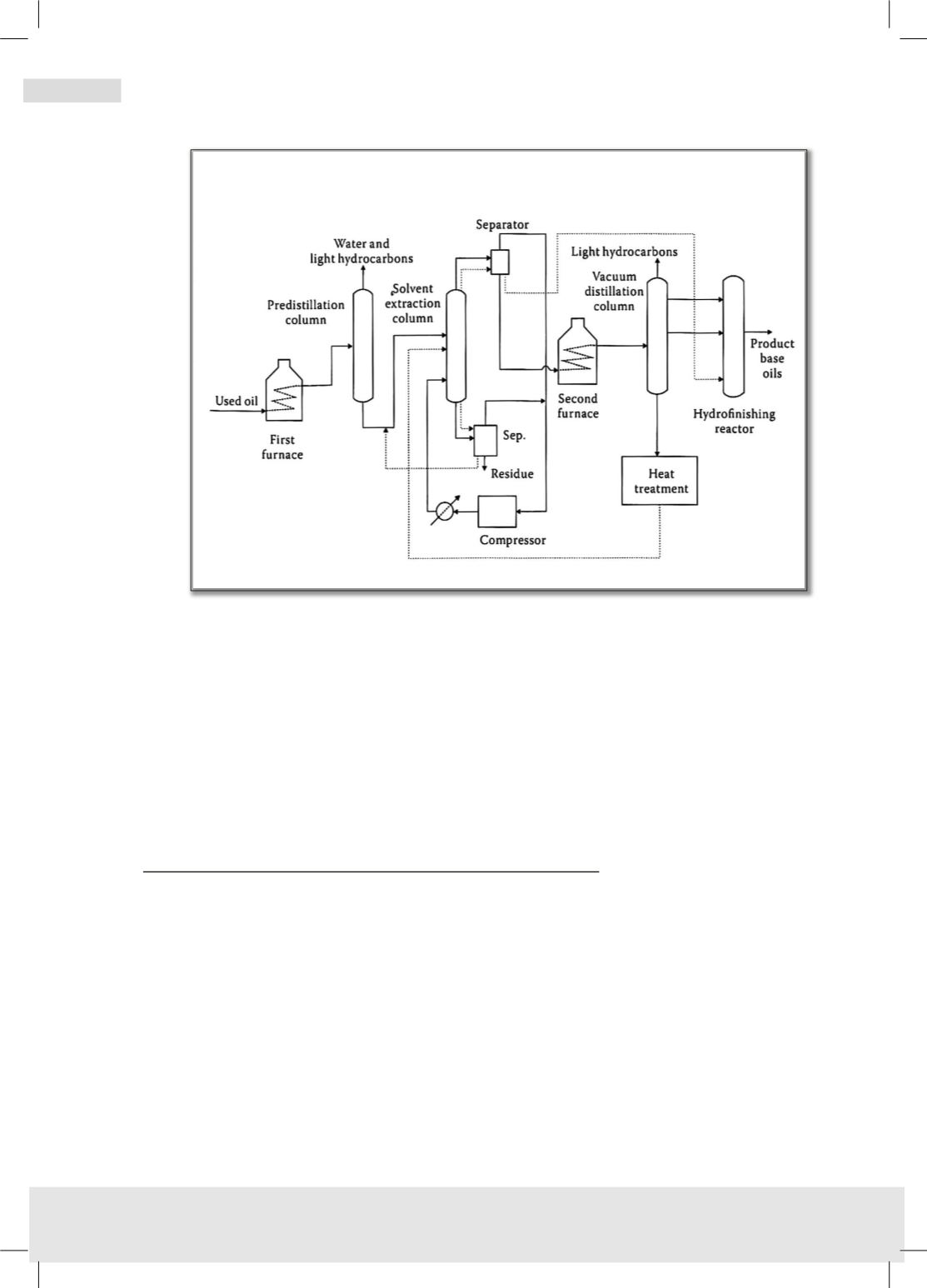

Fig (10) - Snamprogetti Process - Source 1, 3

The heavy base oil can be separately heated and recycled in batch mode to the

solvent extraction stage to improve the cut.

The base oil yield is 87%. The hydro-treater operates at 250 to 450

o

C and the

hydrogen is reported to be between 15 and 850 normal litres/litre

1

of oil. One

plant of 55 thousand tons a year is in Italy.

The Kinetic Technology International (KTI) Process:

1, 4, 67, 107

Fig (11). Patented in 1990, this process passes settl d and filtered used oil into a

distillation column to separate water and light hydrocarbons, which are used as

process fuel or burned in a special incinerator (not shown in the diagram). The

pre-treated oil is then passed into a predistillation column operating under

vacuum and 220

o

C to remove a gasoil stream.

The bottom is partially re-boiled and sent back to the predistillation column and

the other part goes in to a wiped film evaporator operating under very low vacuum

and 345

o

C. The bottom stream of the wiped film evaporator is an asphaltic residue

carrying some contaminants and is partially recycled.