البحـث الأول

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

57

47

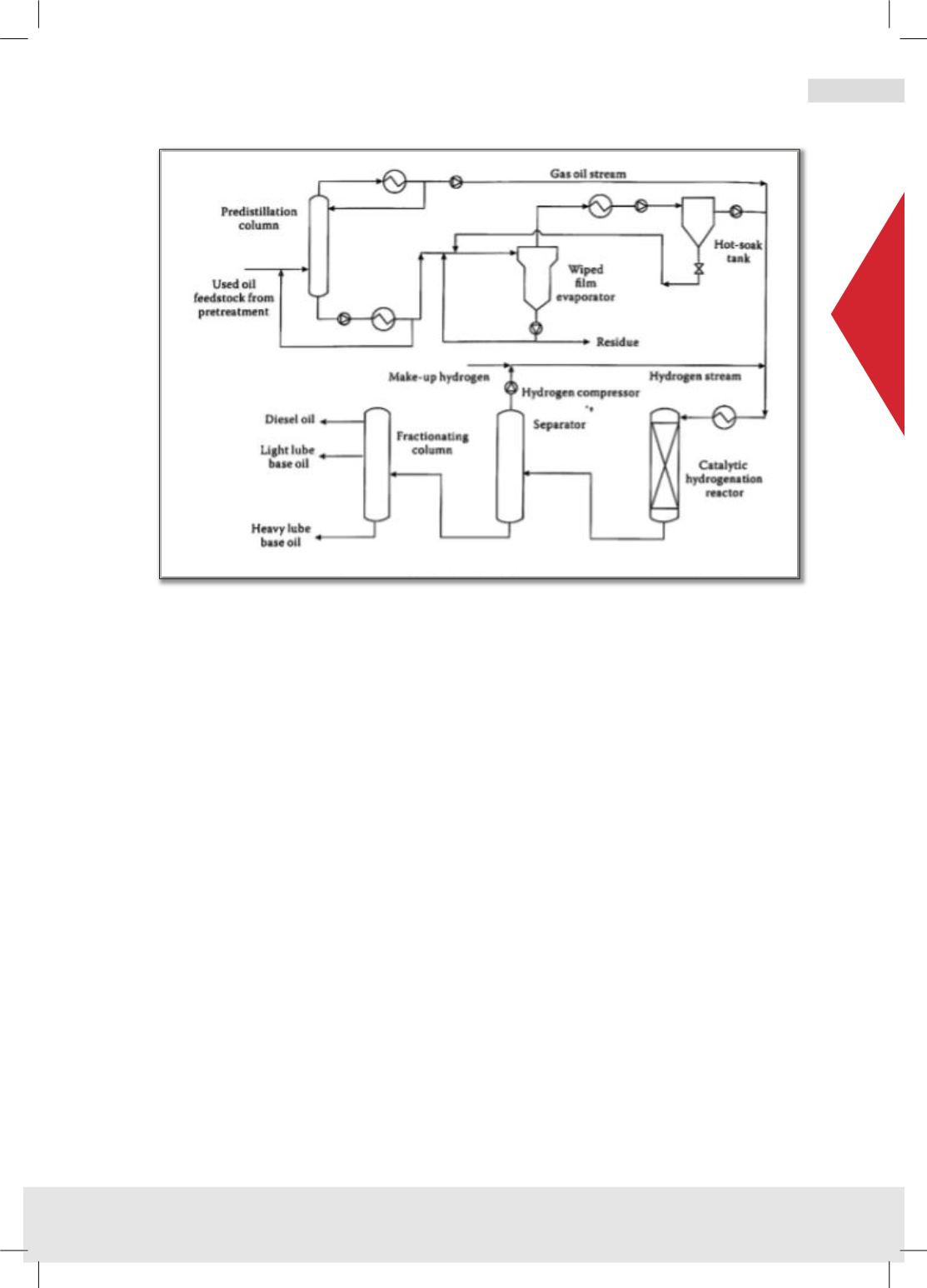

Fig (11) - The KTI Process - Source 1

The top stream is oil vapour which is condensed before entering a hot soak vessel

where heavy impurities settle and recycled back to the front end of the wiped film

evaporator. The hot soak vessel operates at 150 to 250

o

C and the residence time

is 11 to 30 hours depending on the quality of the feedstock. The overflow of the

hot soak vessel joins the gasoil stream and goes into the catalytic hydro-treating

reactor operating at 320

o

C and 870 psi pressure to reduce or eliminate the

impurities of metals, sulpher, nitrogen, chlorine and oxygen. The rest is to

separate and recycle the hydrogen and a fractionation tower finally to separate

the diesel, light and heavy base oils. The KTI Process recovers over 95% of lube

oil components, much higher than other conventional processes though some

sources quote 82%

4

.

Like in other processes, the hydrofinishing step is capable of destroying PCBs

and other similar carcinogenic contaminants. The waste water is treated according

to local regulation of the plant. The base oil quality is equal or better than virgin

base stocks.