مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

58

48

Re-refining plants using this process are in Greece, Tunisia, California and

Germany. The Greek plant (1992) is the first KTI license with 20 thousand tons

a year capacity later raised to 40 thousand tons a year.

The Hylube Process:

1, 3, 86, 107

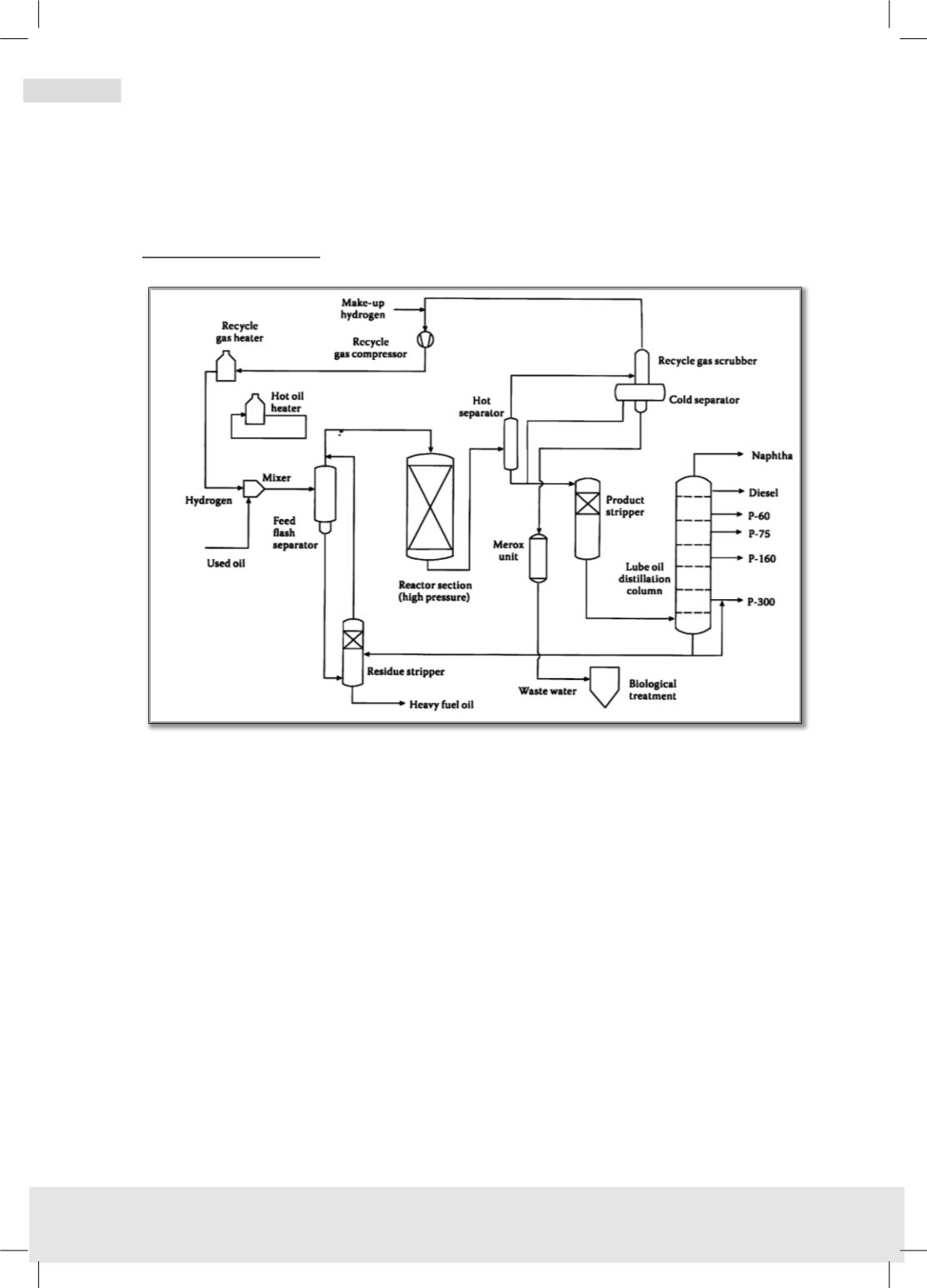

Fig (12) - The Hylube Process - Source 1

Fig (12). First patented by UOP in 1989 and went through many patented

developments later. In this process the settled and filtered used oil is mixed with

hot hydrogen and fed to the flash zone of a column maintained at 380 to 460

o

C.

The bottom stream of the column is the heavy un-distillable portion of the feed

while the top stream vapours are cooled to condense the undesirable heavy

components and separated as low ash fuel oil. The top stream goes to the

hydrofinishing reactor to reduce or remove other contaminants such as metals,

sulpher, nitrogen, and chlorine and oxygen compounds. If PCBs are present in

the feed, they are converted to un-harmful materials. The reactor effluent is

cooled and hydrogen is recovered in a high pressure separator and recirculated.

A low pressure separator follows where fuel gas is drawn from the top and the