البحـث الأول

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

87

77

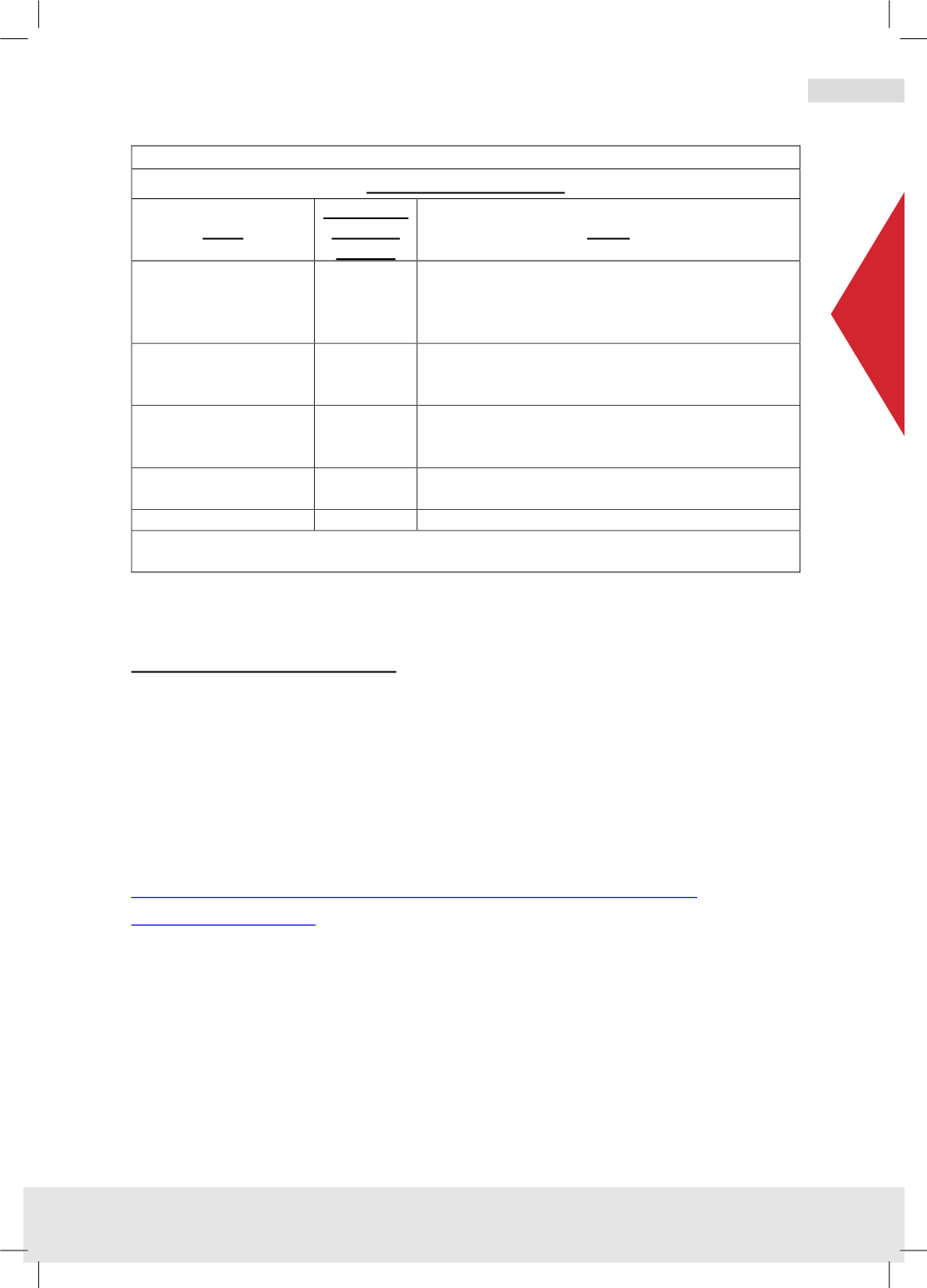

Table (17)

Re-refining Plants in Italy

Plant

Authorised

Capacity

Ktons/y

Notes

Viscolube (Lodi)

130

This plant evolved from propane solvent extraction

to thermal de-asphalting and high pressure hydro-

treating and the Revivoil process to produce Group

II base oils

Viscolube (Frosinone)

84

Produces Group I base oils. Uses double propane

deasphalting followed by low pressure hydro-

treating.

Ramoil (Naples)

35

Produces mainly fuel and a limited quantity of

Group I base oils. Uses thin film evaporator and acid

clay.

Siro (Milan)

9

Re-refining of transformer oil only with acid clay

process.

TOTAL

258

Source: Adapted from GEIR Statistics 2010 as reported in (1) and elaborated by author. 103

and 104. Also private information.

Important Economic Model:

In the book “Refining Used Lubricating Oils”

1

the authors James G. Speight and

Douglas I. Exall used an extensive model to study the economics of re-refining

projects and made the model available on the Internet for the book readers to use.

The model for a small plant is with distillation and clay treatment while the model

for a large plant is for hydro-treating. Both models can be downloaded using the

link:

https://www.crcpress.com/Refining-Used-Lubricating-Oils/Speight-Exall/9781466551497

It is generally accepted that for smaller plants of up to 20 thousand tons a year,

the simpler type of plant such as distillation/clay treatment may provide better

economic returns, and larger throughputs may justify the use of a hydrogenation

step.

The two models are summarised in the following Table (18).