154

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

31

compounds, oxidized hydrocarbons and solids in suspension are also separated in this

stage. The bright stock is recovered from the vacuum residue by propane deasphalting.

The final stage is the hydrogenation of the bright stock fraction.

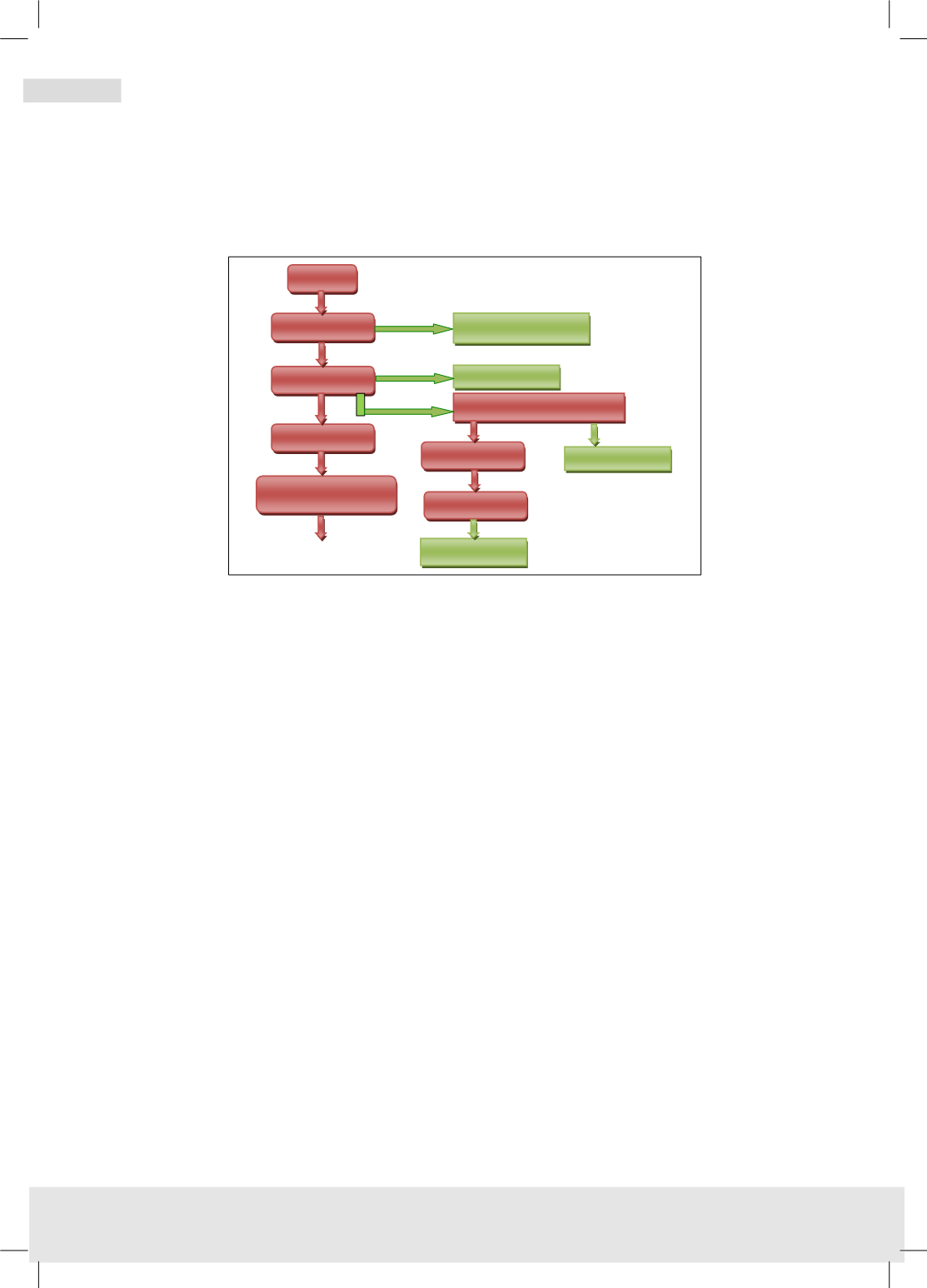

The process is shown schematically in Figure 16.

Figure 16 IFP simplified block flow diagram

Source: UNEP (2012)

4.9.2

Process features and drawbacks

Possibility to produce several base oils with various characteristics.

4.10 Snamprogetti process

The Snamprogetti process is similar to the IFP technology in that it uses the same

processing steps including propane extraction. Snamprogetti has modified the process

by adding a propane extraction step before and after vacuum distillation.

4.10.1

Process description

The process consists of four steps:

Atmospheric distillation:

In this stage, water and light hydrocarbons are eliminated in the extraction column..

Solvent extraction:

Next, waste oil from atmospheric distillation is refined with liquid propane at 75–95 ºC

in the propane de-asphalting(PDA)unit. With this step, the majority of the contaminants

such as asphalt compounds, oxidized hydrocarbons and suspended solids are separated

from the oil.

Waste

Atmospheric

Vacuum

Hydrogenation

Light and médium Base oils

Water and lights

Gas oil

Extraction using Propane

Asphalt

Demetallization

Separator

Bright stock