البحـث الثاني

157

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

34

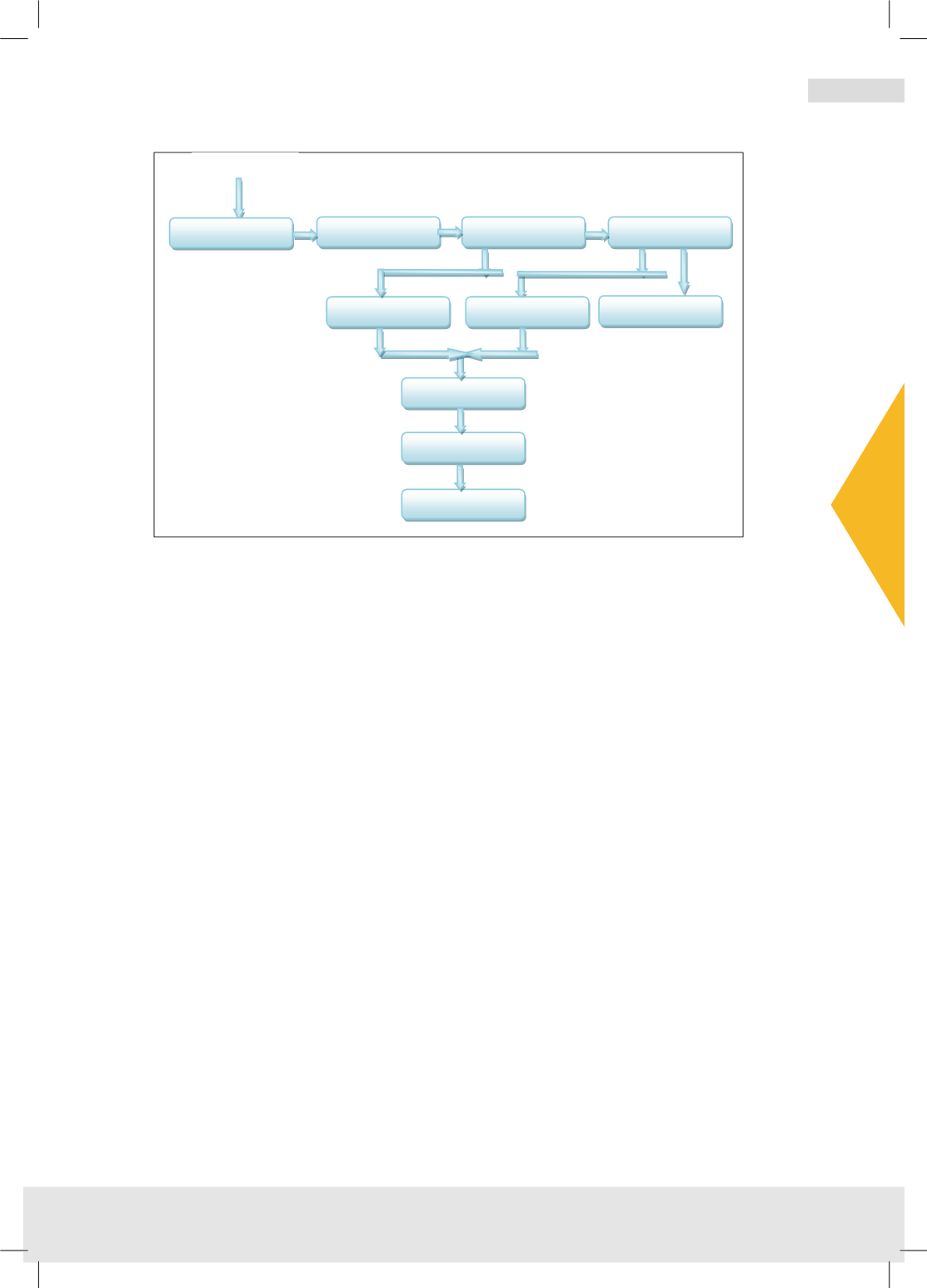

Figure 18 Schematic of the VAXON re-refining process

Source UNEP (2012)

4.12 Interline Technology

This technology was developed by Interline Resources Corporation. It can be applied

for production of different oils for vehicles (e.g. motor oils, transmission oils), industrial

oils and process oils. The European Environmental Press awarded its 2003 Bronze

Medal for

Interline Resources Corp.'s re-refining technology (BW, 2004).

4.12.1

Process description

The basic steps of this process are as follows:

Solvent extraction:

The used oil feed is mixed with propane and the mixture is then sent to a specific

solvent extractor, a proprietary system. Most of the additives, water and other

insolubles are separated from the propane/base oil mixture. Then, the solvent/oil

mixture is pumped to an oil/solvent separation system. The propane is vaporized at a

pressure high enough to allow the propane to be condensed at the cooling water

temperatures. The recovered propane is then returned to the solvent extractor to be re-

used with incoming used oil.

Flash and Vacuum distillation:

Propane free oil is sent to a light hydrocarbon stripper where the last traces of propane

and low-boiling hydrocarbons (gasoline) are removed.

Waste oil

Distillation2

Distillation3

Distillation4

Distillation1

Distilled oil

Asphalt

Distilled oil

Chemical Treatment

Vac Distillation

Base Oil