البحـث الثاني

153

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

30

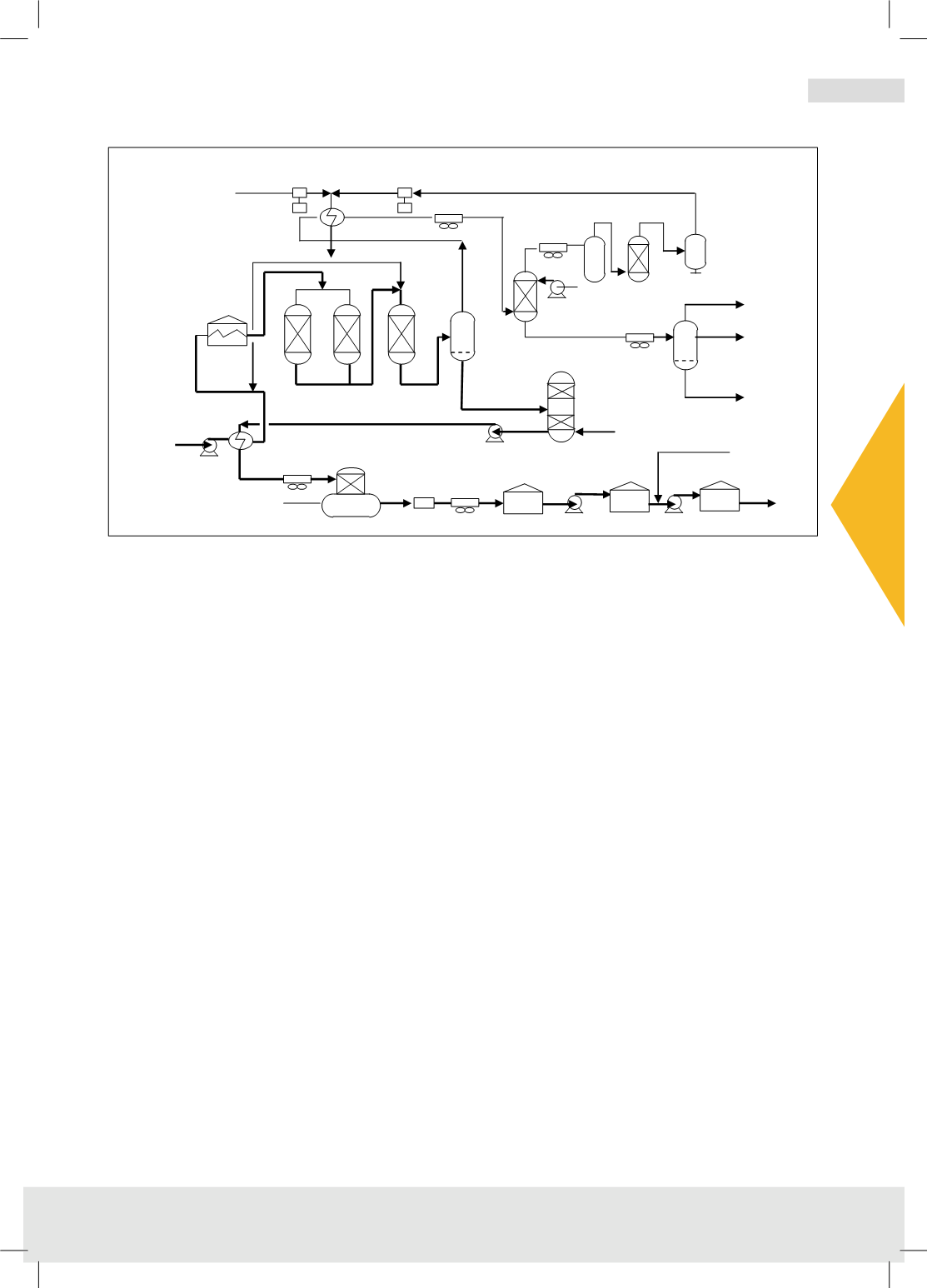

Figure 15 PROP process process flow sheet

Source: Audibert as cited in UNEP (2012)

4.9

IFP technology

IFP technology was developed by the Institut Francais du Pétrole. The principle of this

process, also known as Selectopropane process, is based on the use of propane to extract

selectively all base oil components from used lubricating oil.

4.9.1

Process description

The process comprises the following steps:

Atmospheric distillation:

First, water and light hydrocarbons are removed in the atmospheric distillation column.

Vacuum distillation:

Then, oil from atmospheric distillation is subjected to extraction with liquid propane at

a temperature of between 75 and 95ºC. Light and medium base oils are recovered in this

phase.

Hydrogenation:

In this step the vacuum distillates are hydrotreated to produce finished base oils. This is

the stage where the propane is separated from the propane-oil mixture. Asphaltic

Stripping

by air

Base Oil

Storage

Storage

Filter.

Air.

Demetallized

used oil

Flash

vessel.

Washing.

Water.

Used water

Light HC.

Washing

soda

Steam

Guard

reactors

Catalyst

reactor

H2 makeup

H2 recirc.

Stripper.

To flare.

Additive