البحـث الثاني

155

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

32

Vacuum distillation:

In this step base oil is recovered as distillate and sent to hydrogenation unit for further

treatment. The vacuum distillation waste is sent through a second extraction, using

propane, which is combined together with the vacuum distillate in the hydrogenation

unit.

Hydrogenation:

In this final stage, base oils with different properties are produced in the

hydrotreatment unit. The bright stock fraction is also recovered from the waste from

vacuum distillation.

4.10.2

Process features and drawbacks

There exists the possibility to produce several base oils with various characteristics. The

PDA bottoms are used in the asphalt production. The solvent is recycled in the process

with minor losses (5~10%).

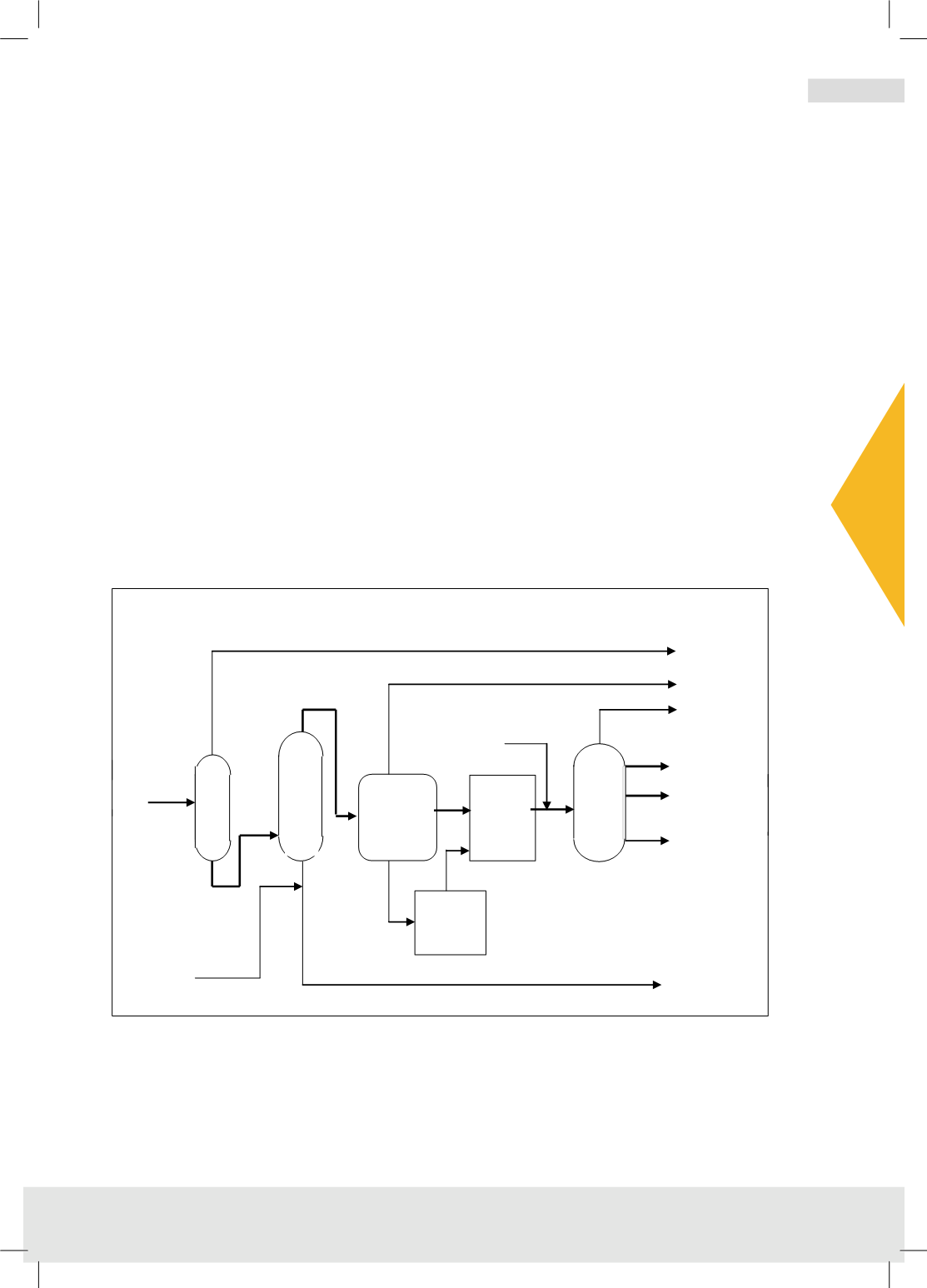

Figure 17 illustrates the simplified process flow sheet of the SNAMPROGETTI process

Figure 17 Snamprogetti simplified process flow diagram

Source: Snamprogetti

Diluting

fuel

Asphalt

Water+Light

HC

Medium base

oil

Light base

oil

Bright stock

Fuel gas

VGO

Hydrogen

Waste Oil

Vacuum

distillation

Storage

Extraction

using

propane

Hydrofinishing

Propane extraction

Predistillation