البحـث الأول

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

53

43

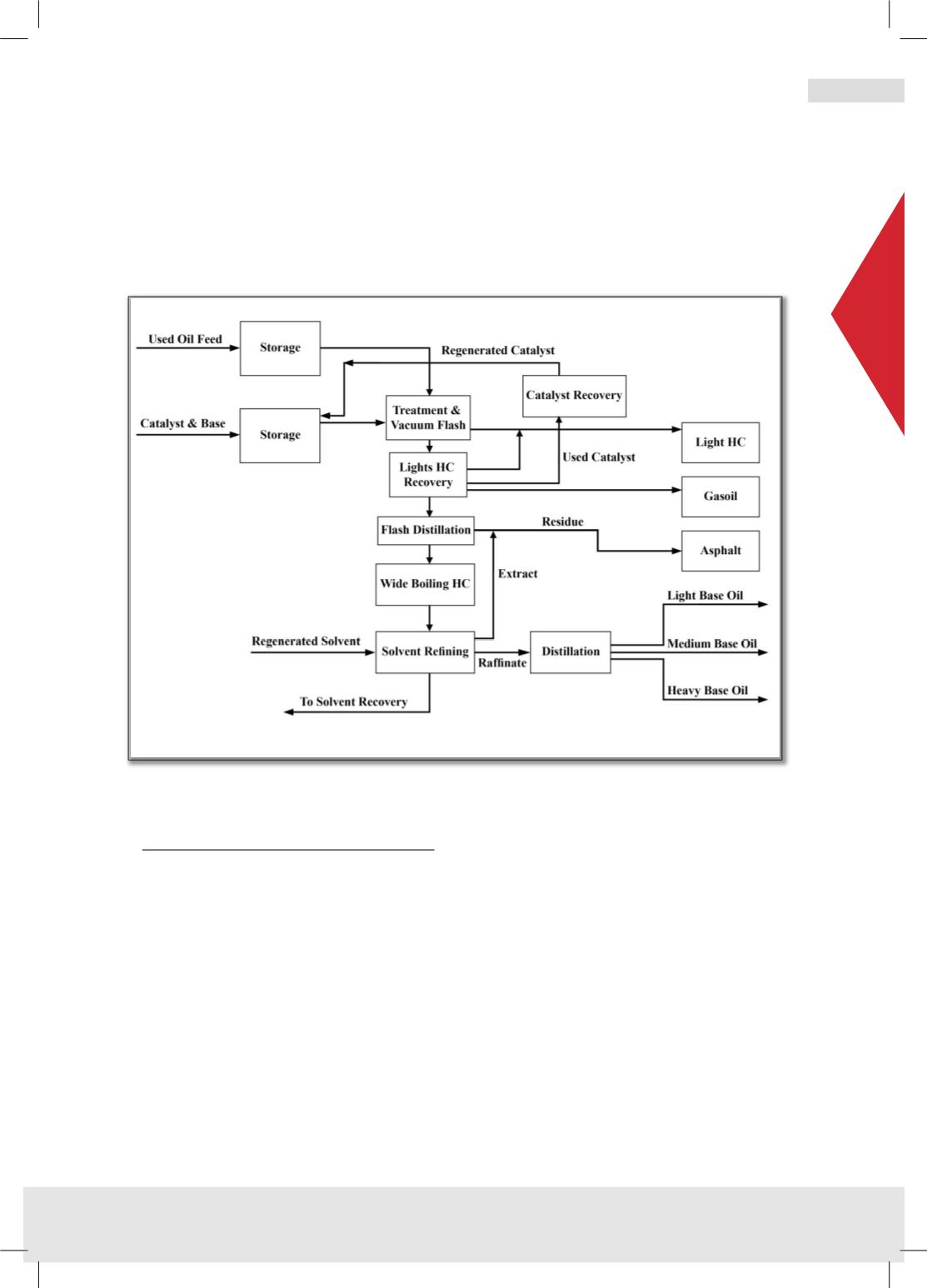

The process does not cause pollution except for some solvent losses and produces

relatively good quality base oils. Avista Oil Company owns and operate a 35

million gallons a year re-refinery in the US and another three plants in Saudi

Arabia (2003) and one in Denmark (2008).

Fig (7) - Avista Process - Source 3

Viscolube and the Revivoil Process:

1, 15, 87

Fig (8). The original Viscolube process is an example of chemical treatment,

distillation and clay. After settling and filtration the used oil feed is treated with

30% caustic soda (sodium hydroxide) solution to neutralize fatty acids and

chlorides before water and light hydrocarbon removals are made in a pre-flash

tower operating under vacuum and 120 to 140

o

C. The bottom of the pre-flash

column goes to a settling tank where impurities are removed before the used oil

is heated to 360

o

C and flashed in a deasphalting and fractionating vacuum tower

with a cyclone separator in its bottom. The side streams of base oils are stripped

by steam in in the next columns and treated by clay to remove odour and improve

colour. The light products can be used as fuel in the plant. The process is a