البحـث الثاني

145

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

22

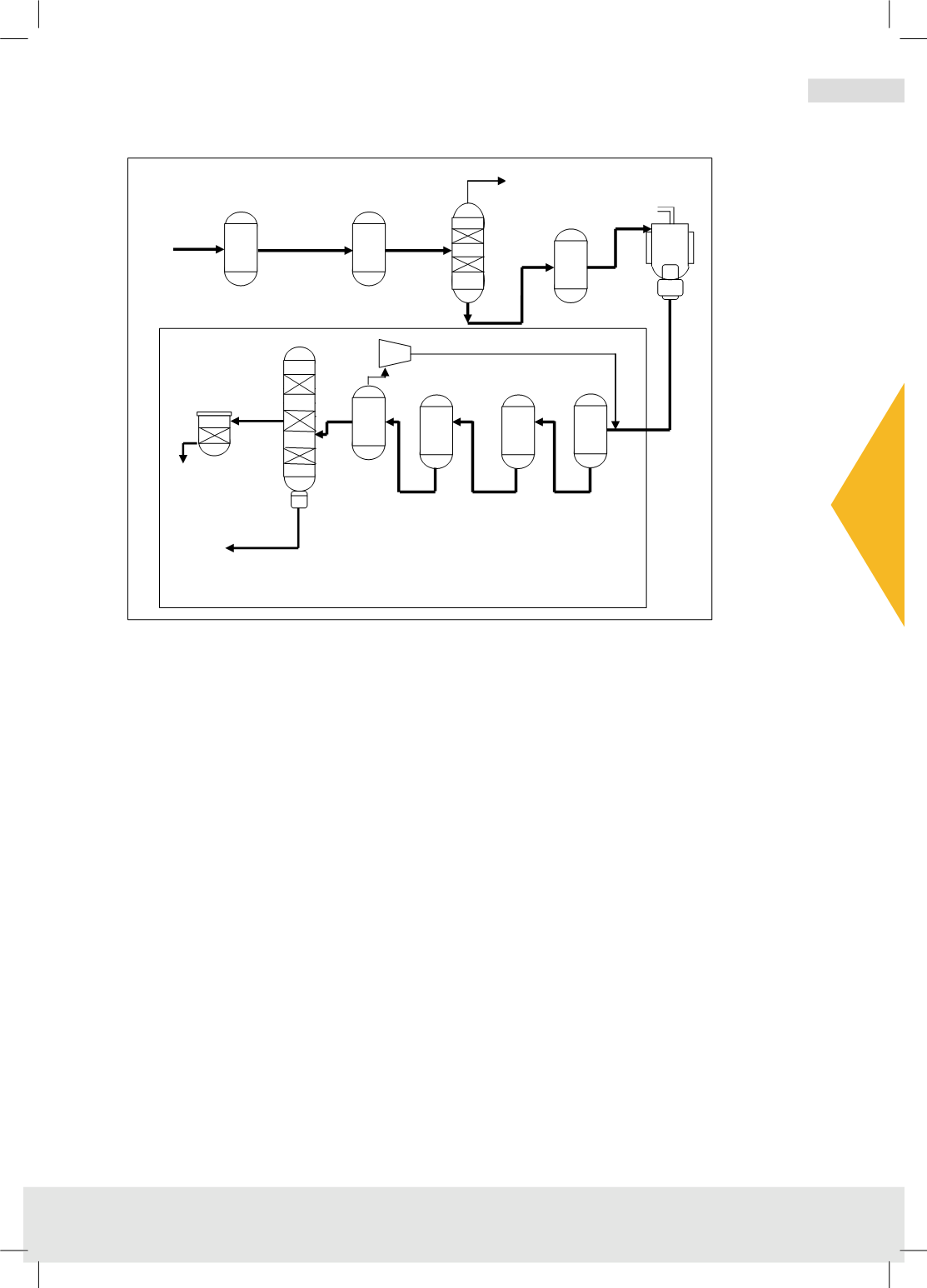

Figure 10 CEP simplfied process flow diagram

source: CEP

4.4

UOP Hylube process

4.4.1 Process description

This technology was designed by UOP in 1995. This process which operates on

continuous basis is made up of the following stages:

Pretreatment:

The feedstock is first filtered to remove solids and then mixed with hot hydrogen in a

pressurized mixing chamber. The heat mixture is sent to flash separator where the

bottoms are routed to a residue stripper.

Hydroprocessing:

In the multi-stage high-pressure system, the gaseous hydrocarbon materials are initially

separated from the residual impurities and metal compounds (guard reactor), and then

processed through a severe hydofinishing reactor. Using patented hydrogenation

catalysts, a deep saturation of olefins and aromatics is achieved (conversion reactor),

2nd reactor

3rd reactor

1st reactor

Recycle gas

Heavy base oil

Waste Oil

Wáter and light

Hydrocarbons

Gas Oil

Light base

oil

Fractionati

o

Wiped film

Evaporator