146

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

23

which are then hydro finished at adequate high temperatures and pressures. These

processes involve intense desulphurization and elimination of other impurities.

Product recovery:

The processed feedstock is converted into a wide boiling range hydrocarbon product,

which is subsequently fractionated into neutral oil products of different viscosity to be

used for lube oil blending.

4.4.2 Process features and drawbacks

It is claimed that the Hylube process achieve more than 85% of base oils suitable for re-

blending into saleable lube oils. It is reported that Lube base stocks quality is equal to

virgin base oils (ref.) It is also claimed that no environmentally undesirable by-products

are produced. The heavy residue is suitable for asphalt blending. The aqueous effluent

has low COD and no organochlorines.

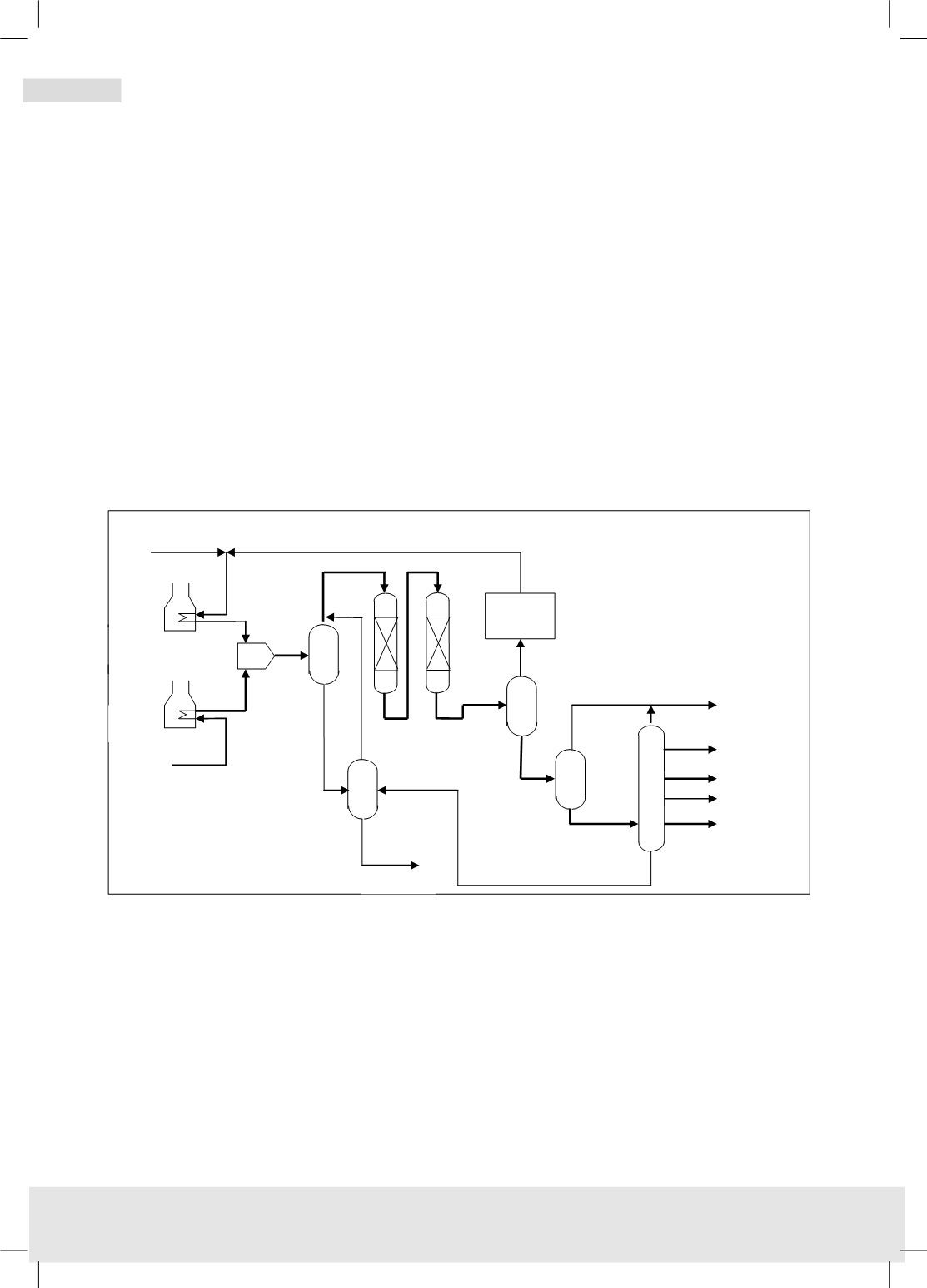

Figure 11 UOP Hylube simplified process flow diagram

Source: UOP

4.5

Axens/Viscolube (Revivoil) process

The Revivoil process was developed jointly by Axens and Viscolube. It combines two

technologies: thermal deasphalting and catalytic hydrogenation.

Vacuum Gas

Oil

Light Base

Oil

Heavy Base

Oil

Fractionation

Column

High Pressure

Separator

Hydrogenation

Reactor

Guard

Residue

Flash

Blender

Preheater of

Recycled

Feed

Preheater

Used Oil

Residue

Stripper

Asphaltene

Product

Stripper

Light

Hydrocarbons

Recycled H2

Fresh H2

Gas

purifier