142

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

19

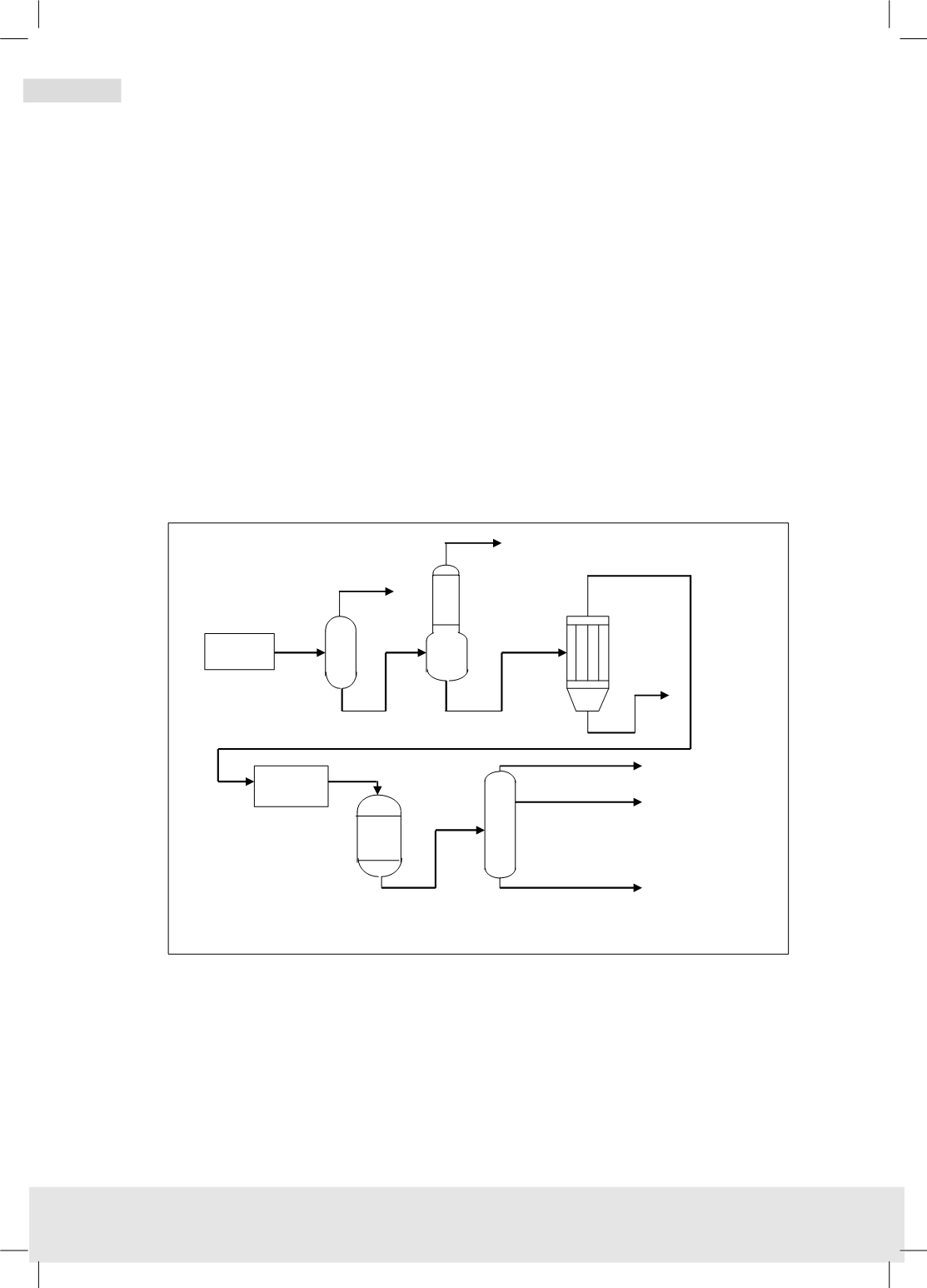

Finally, the re-refined base oil is separated into different oil grades: Light viscosity

lubricants suitable for general lubricant applications, low viscosity lubricants for

automotive and industrial applications and high viscosity lubricants for heavy duty

applications (Fernatt, 2013).

The process main steps are outlined in Figure 8.

4.1.2 Process features and drawbacks

It is claimed that the base oils recovered by this process meet API standards for base

oils. Lubricants made from Safety Kleen base stock include engine oils, gear lubricants,

power transmission fluids, hydraulic oils, and industrial oils, all of which meet industry

standards and specifications and therefore do not jeopardize warranties or the

performance of equipment (UNEP, 2012).

Figure 8 Safety Kleen simplified process flow diagram

Source: Fernatt (2013)

Distillate

Asphalt

H2O

Vacuum

Distillation

Fuel Stripper

Dehydration

Unit

hydrotreater

Vacuum

Fractionation

Fuel

Used Oil

Vacuum

Oil

Base oil cut 70

Base oil cut 240