148

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

25

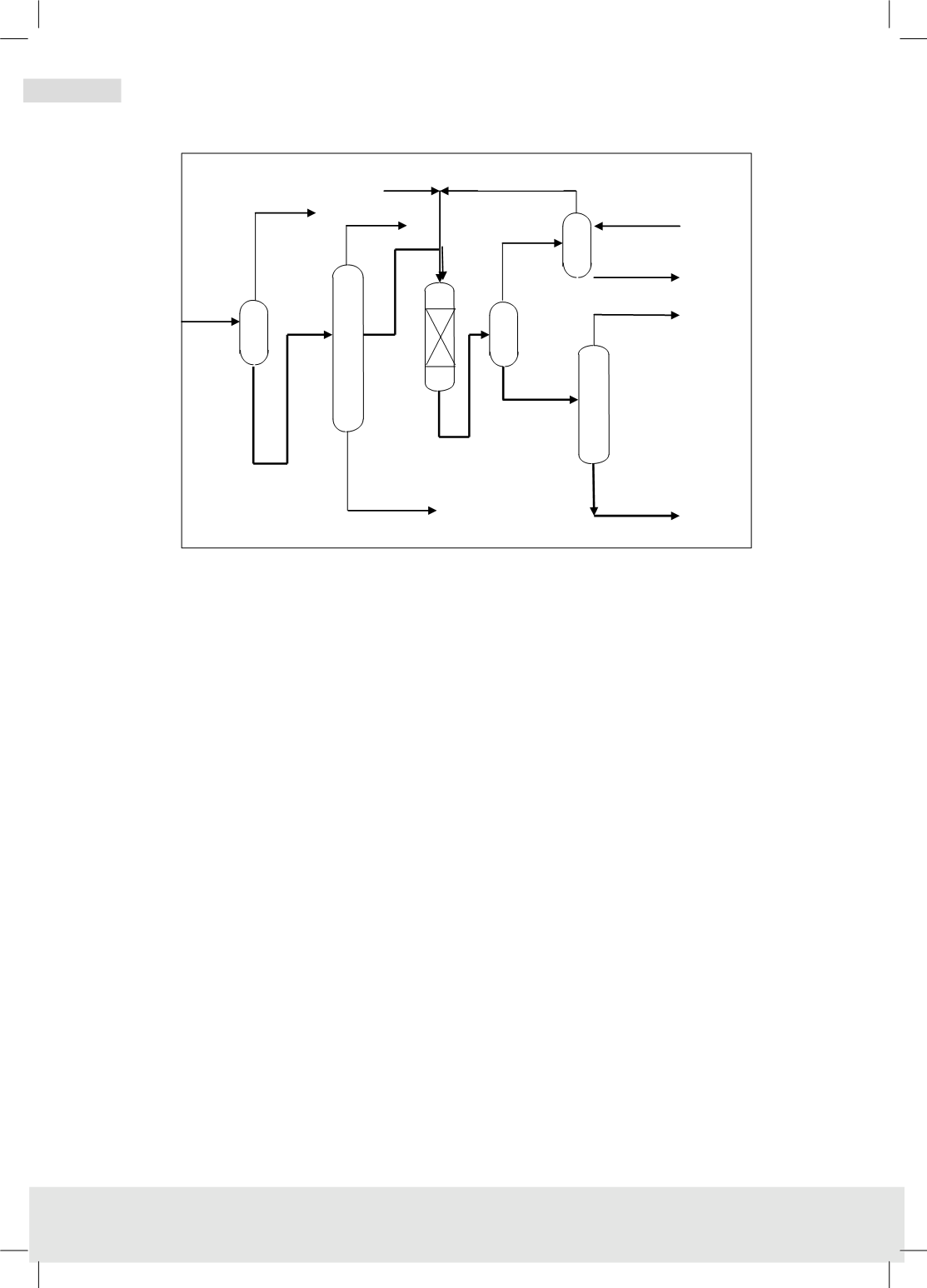

Figure 12 Revivoil simplified process flow diagram

Source: Petder (2012)

4.6

STP Process

STP (Studi Tecnologie y Progetti) is the supplier of this re-refining technology which is

based on thin film evaporation and hydrofinishing.

4.6.1

Process description

The basic steps of the process are as follows:

Dehydration and lights removal:

The stocked used oil is pumped through a filter and preheated through heat exchangers

which help in recovering heat from finished products. It is then treated with chemical

additives. The treated oil is flashed in the flash drum to remove water and light

hydrocarbons. Gases are burnt in a thermal oil furnace. Water and hydrocarbons are

condensed and separated in a settler.

Flash

VGO

Water, light

hydrocarbons

Fresh H2

Flash

Amine

absorber

Light hydrocarbons

Stripper

Fractionation

column

Hydrogenation

reactor

Asphaltenes

Re-refined base oil

Regenerated amine

Used amine

Recycled H2