البحـث الثاني

143

2016

أوابك العلمية لعام

�

ص لبحوث العلمية الفائزة بجائزة

�

عدد خا

مجلة النفط والتعاون العربي

161

العدد

- 2017

أربعون

المجلد الثالث و ال

Re-refining of Used Lubricating Oil and its Economic and Environmental Implications

20

4.2

KTI process

4.2.1 Process description

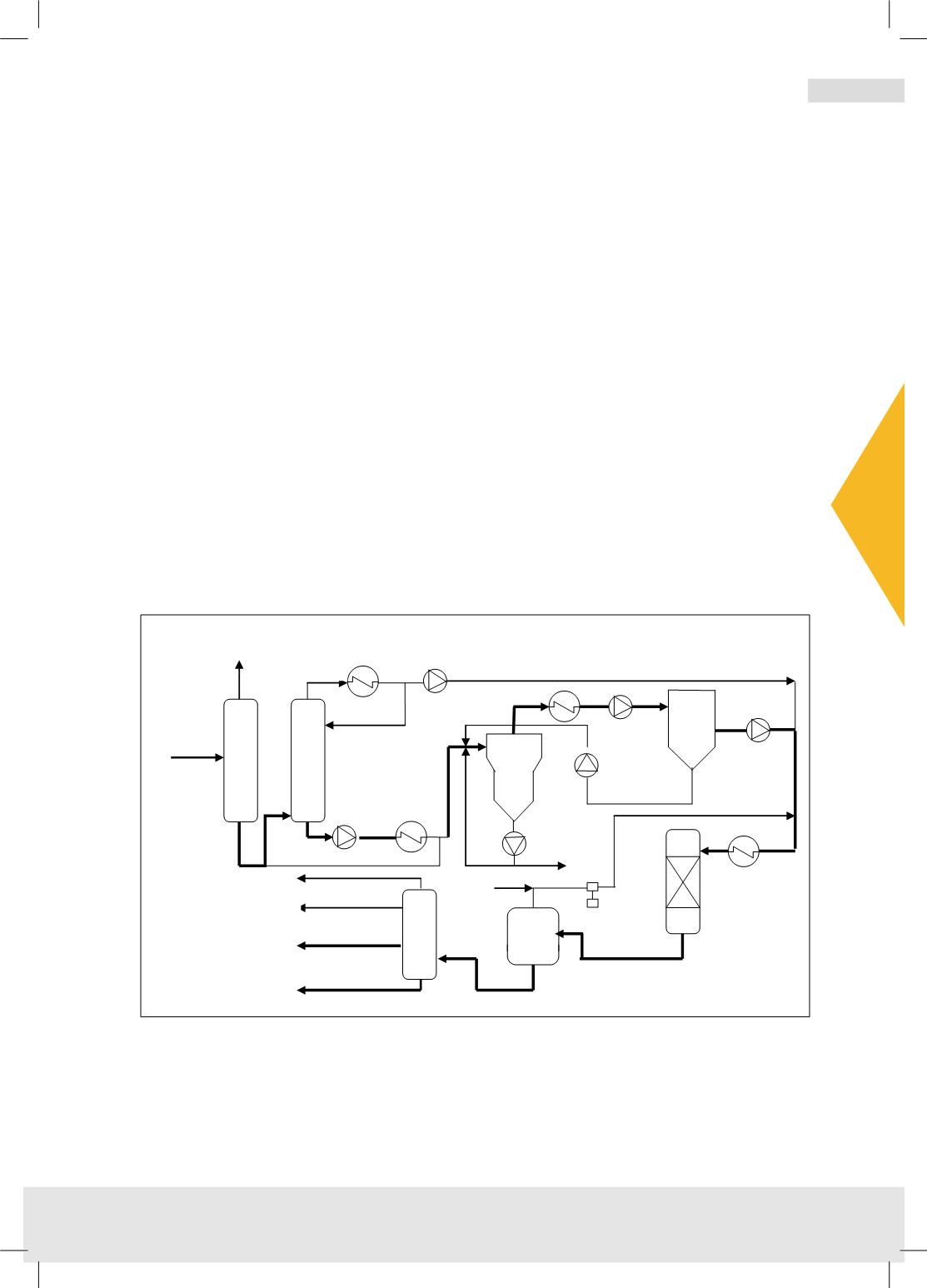

The KTI (Kinetics Technology International) also known as KTI relube is constituted of

the following sequences:

Atmospheric distillation:

In this step, Water and light hydrocarbons are removed.

Vacuum distillation:

Thin film vacuum distillation to produce the lube fraction

Hydrogenation:

The distilled fraction is hydrogenated in order to eliminate contaminants and additives

Fractionation:

The hydrogenated fraction is fractionated into light and heavy oil.

Figure 9 shows a simplified flowsheet of the KTI re-refining process.

Figure 9 KTI simplified process flow diagram

Source: Audibert as cited UNEP(2012)

Fuel gas

Light oil

Heavy oil

Residue

Settling

Vessel

Water and

Light HC

Used oil

PreFlash

Thin Film

Evaporat

or

Diesel oil

Predistillation

¡Hydrofinishing

Separator

Diesel oil

H2